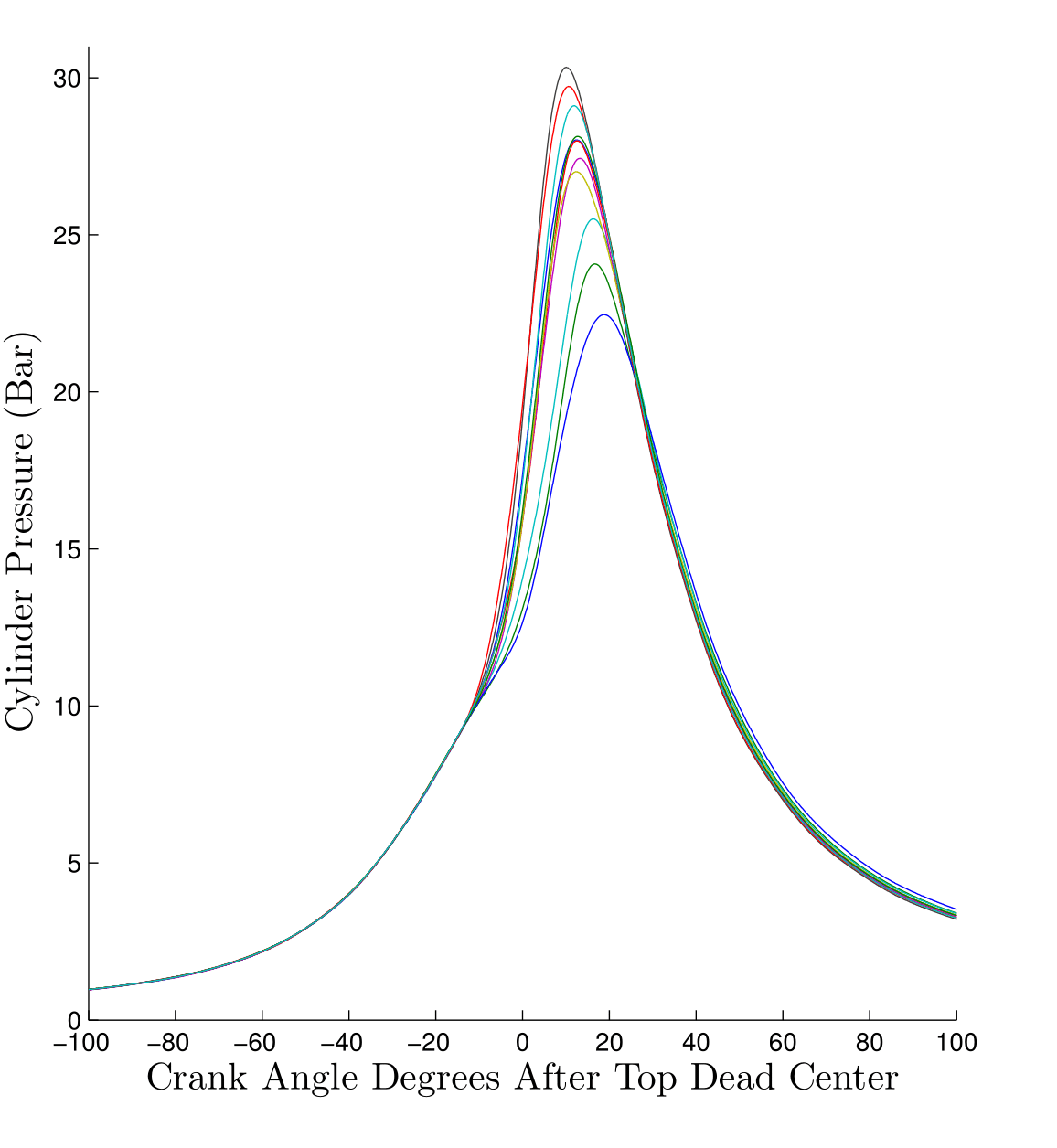

The figure to the right shows the cylinder pressure of 10 consecutive combustion events in a production internal combustion engine. As shown in the figure there is considerable variation between the combustion events after the point of ignition. This variation is called cyclic variability.

The scope of my thesis was three fold:

- Characterize the cyclic variability of the engine used in this study.

- Test whether a minimum variance control method could reduce the cyclic variability.

- Test whether a minimum variance tracking control method could track a reference with no impact on cyclic variability.

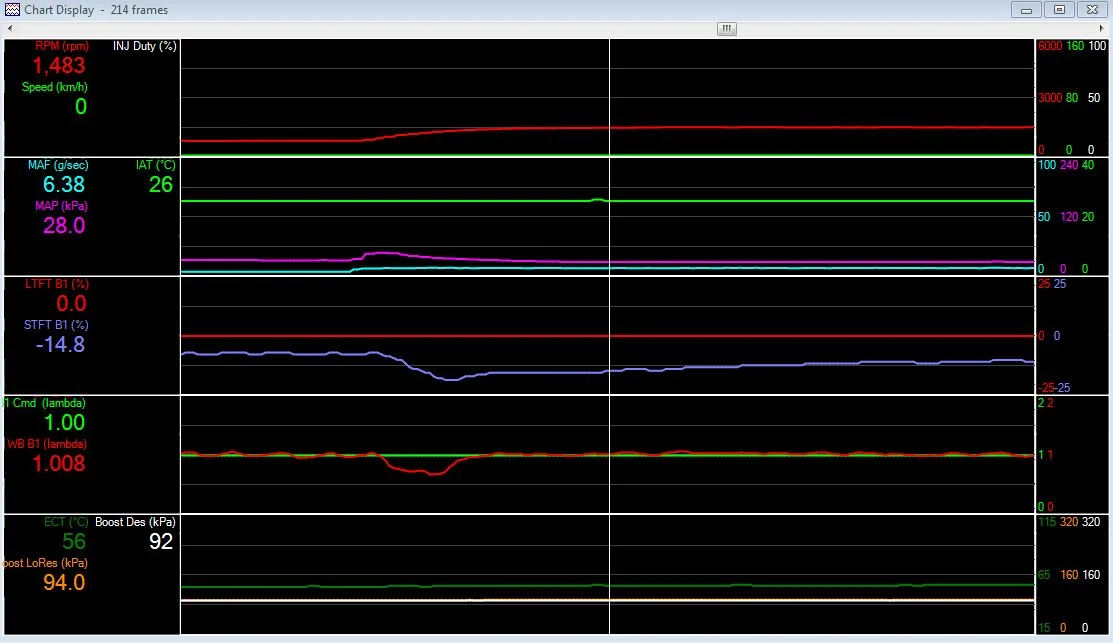

The results of these three tasks was excellent, not very good, and pretty good respectively. For the first task I characterized the cyclic variability using two different fuels a number of different operating conditions. For the task of reducing cyclic variability a reduction 1.4% was achieved.

The third bullet point is slightly more complicated. Engines are hit by both small disturbances (like cyclic variability) and large disturbances (stomping on the gas pedal, turning on the A/C). Most controllers such as PID's only focus on controlling for the large disturbances. A minimum variance tracking controller however is designed with a balance between impact on small disturbances and effectiveness of controlling for large disturbances. I was able to design a controller that had a small impact on cyclic variability compared to other control methods while still being able to track large disturbances.

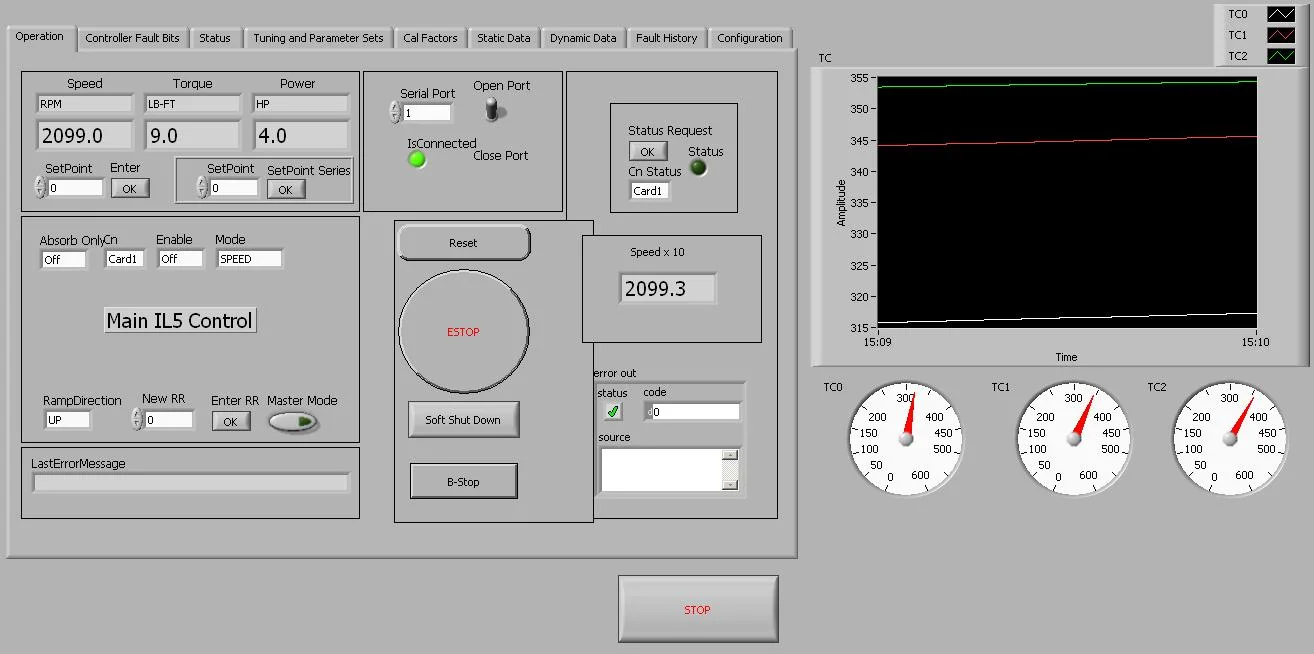

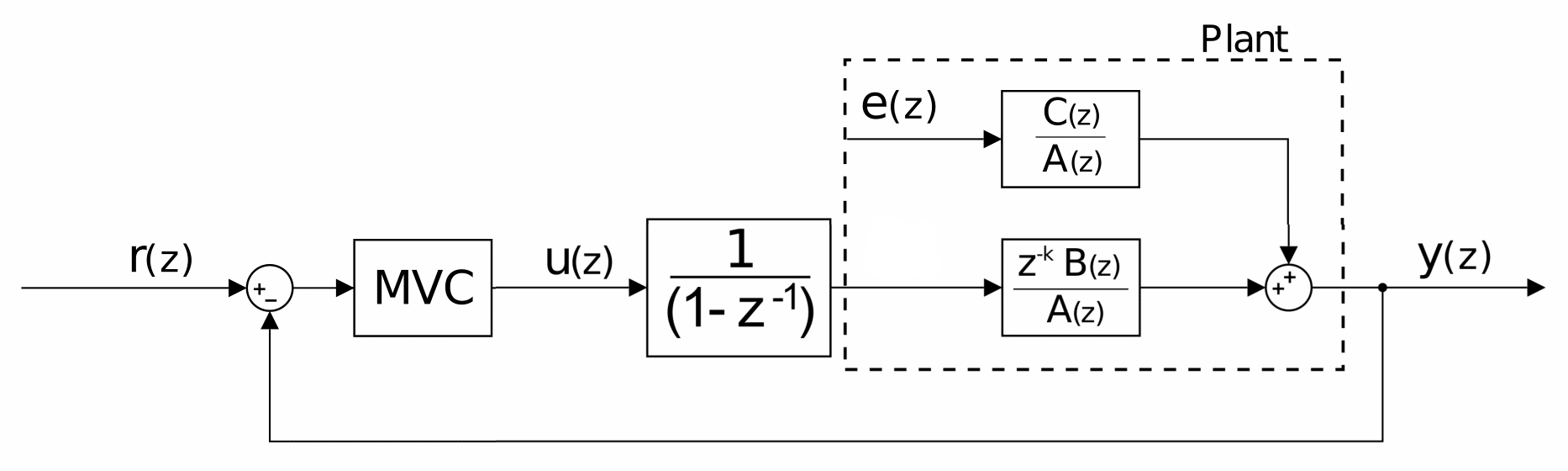

The minimum variance control (MVC) block diagram can be seen below. The engine (plant) is modeled using a system identification ARMAX model and the output of the MVC is multiplied with a integrator as outlined in Astrom - Introduction to Stochastic Control Theory. The MVC controller output u(z) is calculated based on the system identification values (A(z), B(z), C(z)).

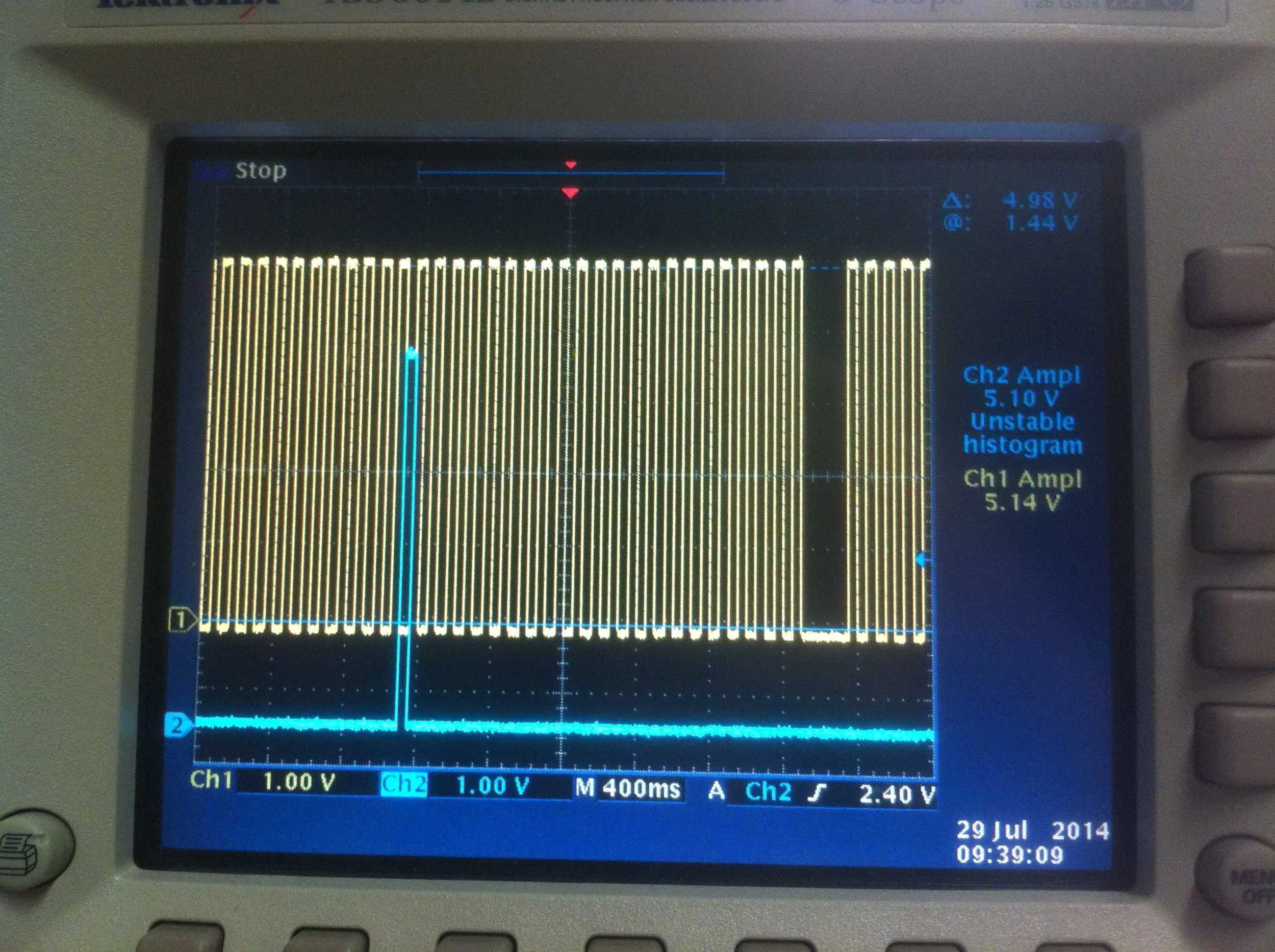

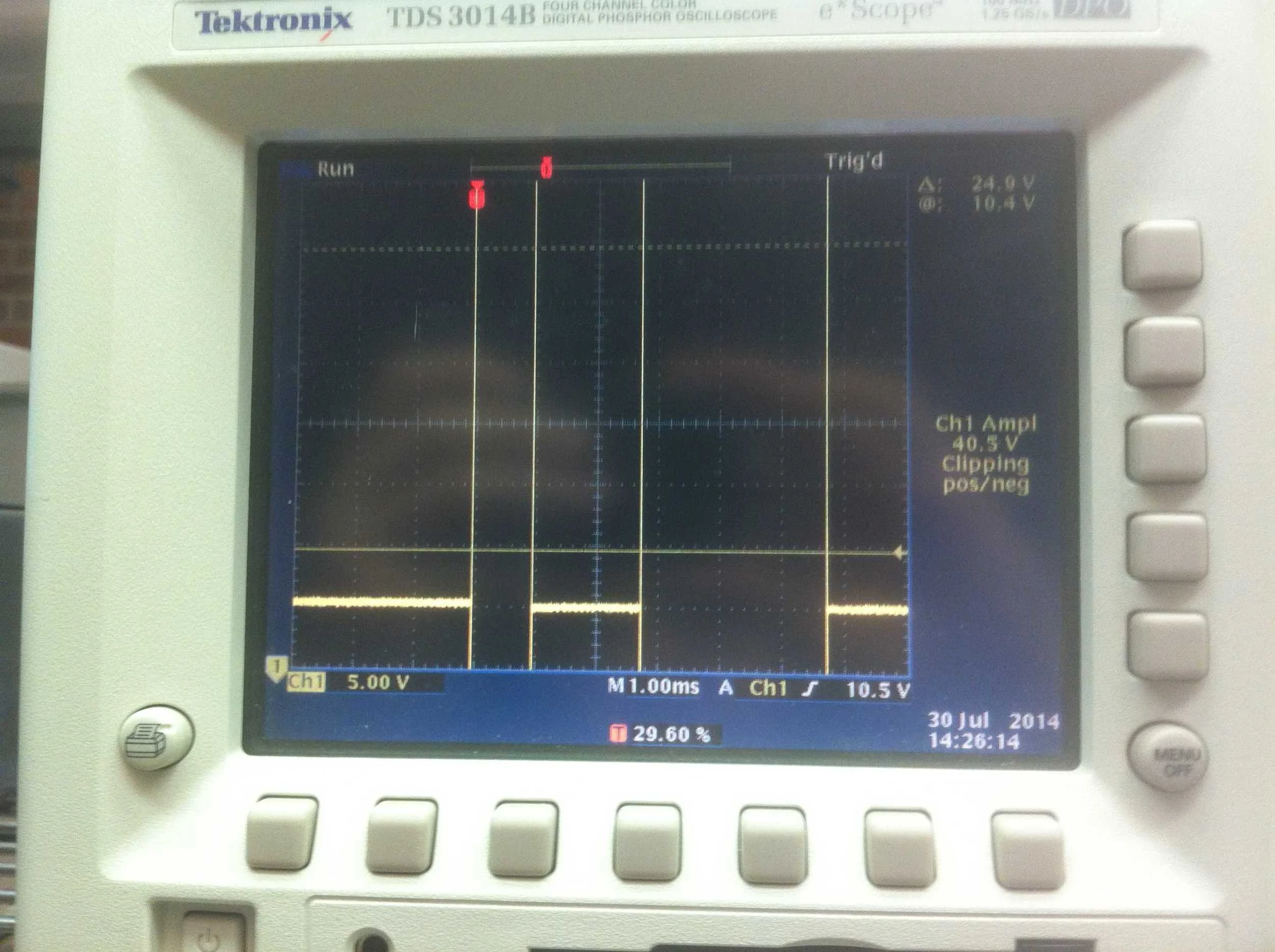

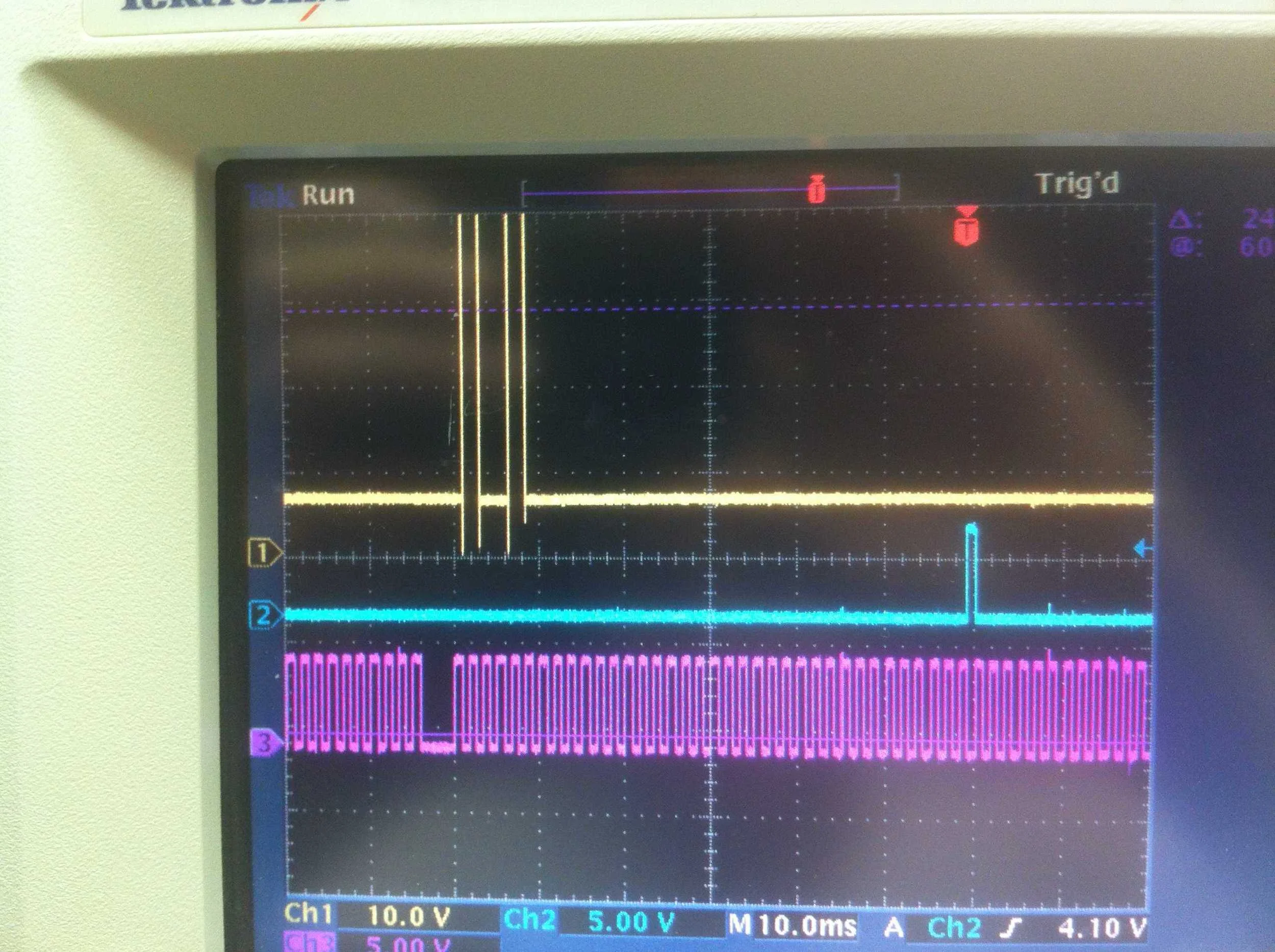

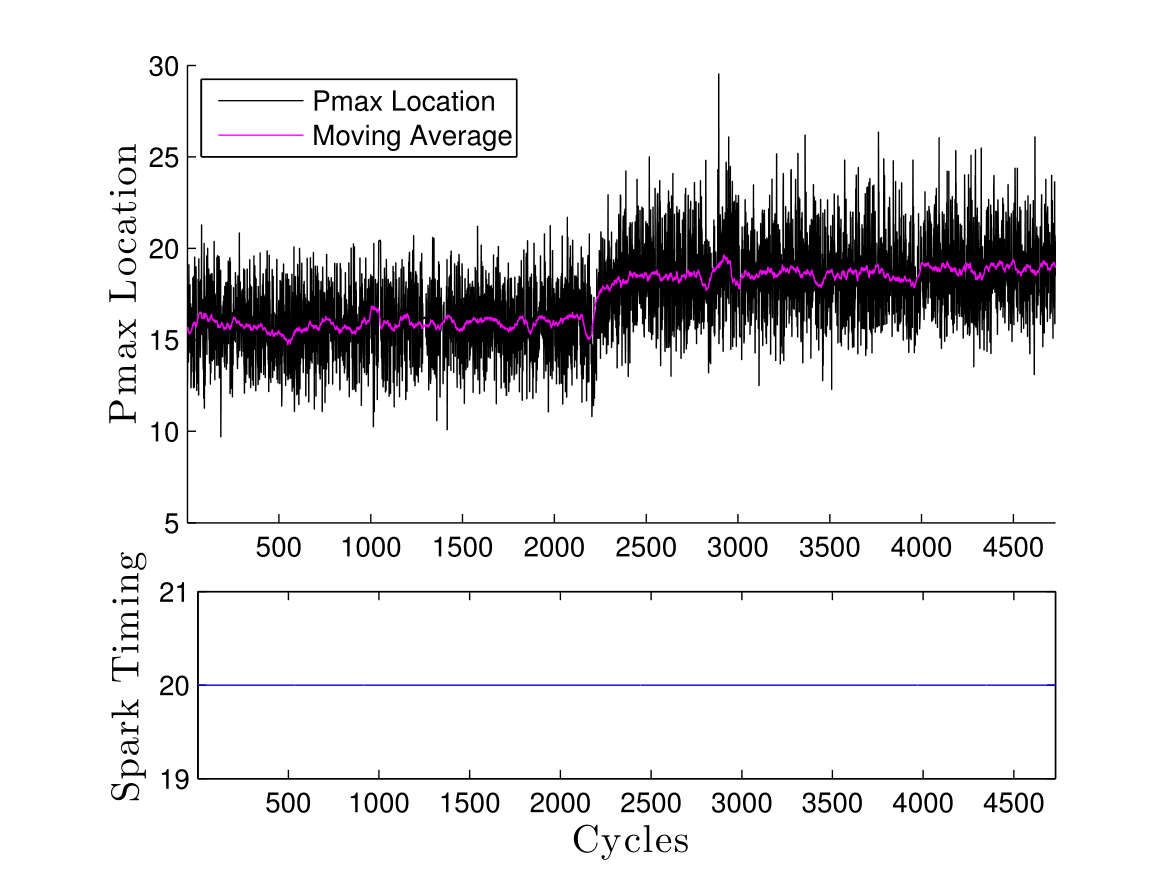

Below are 2 figures from my thesis. The one on the left shows the base case of an engine disturbance without the controller. The right shows the minimum variance tracking controller rejecting the disturbance. The impact of the minimum variance controller was an increase of cyclic variability of 2.6%.

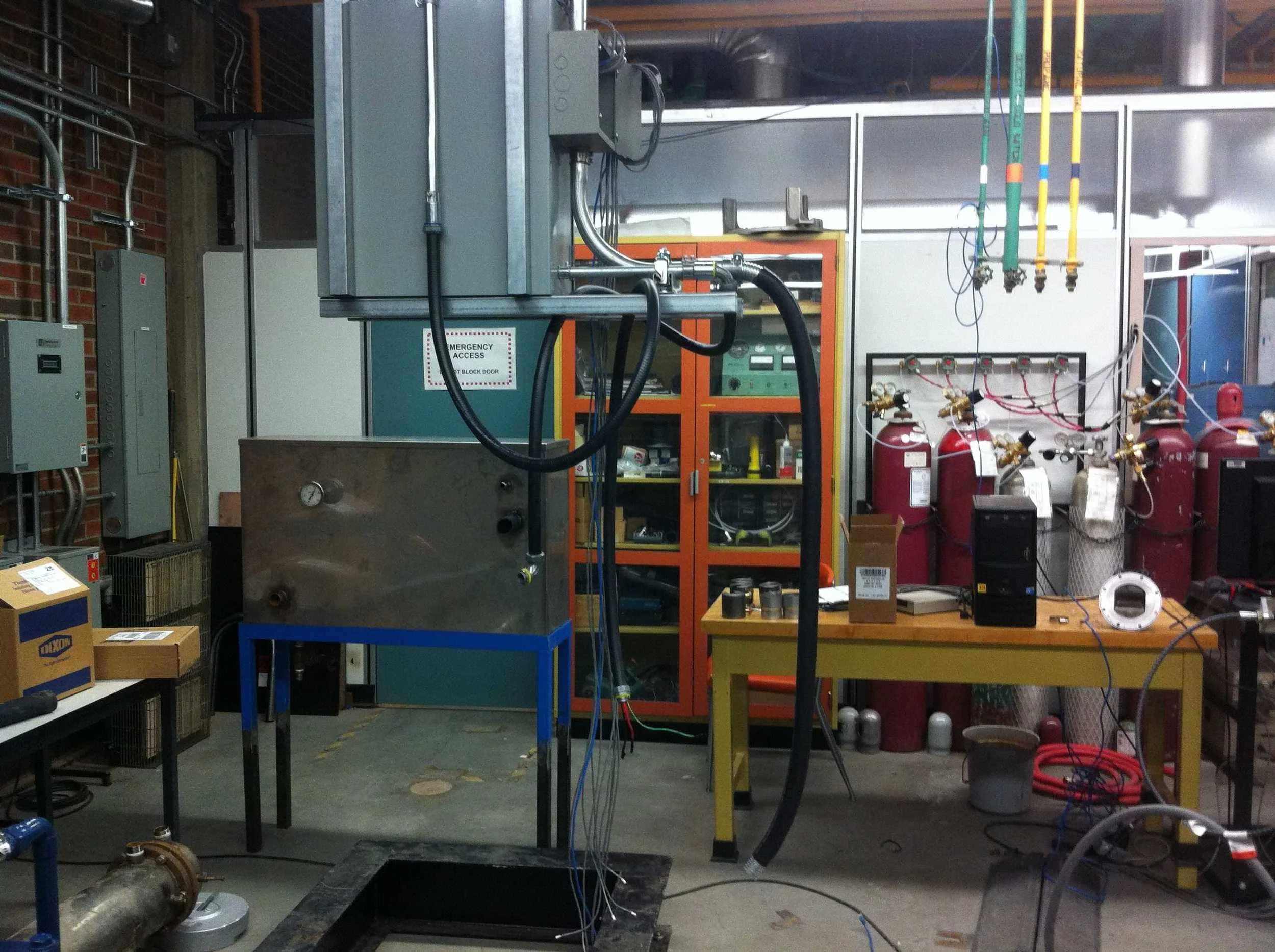

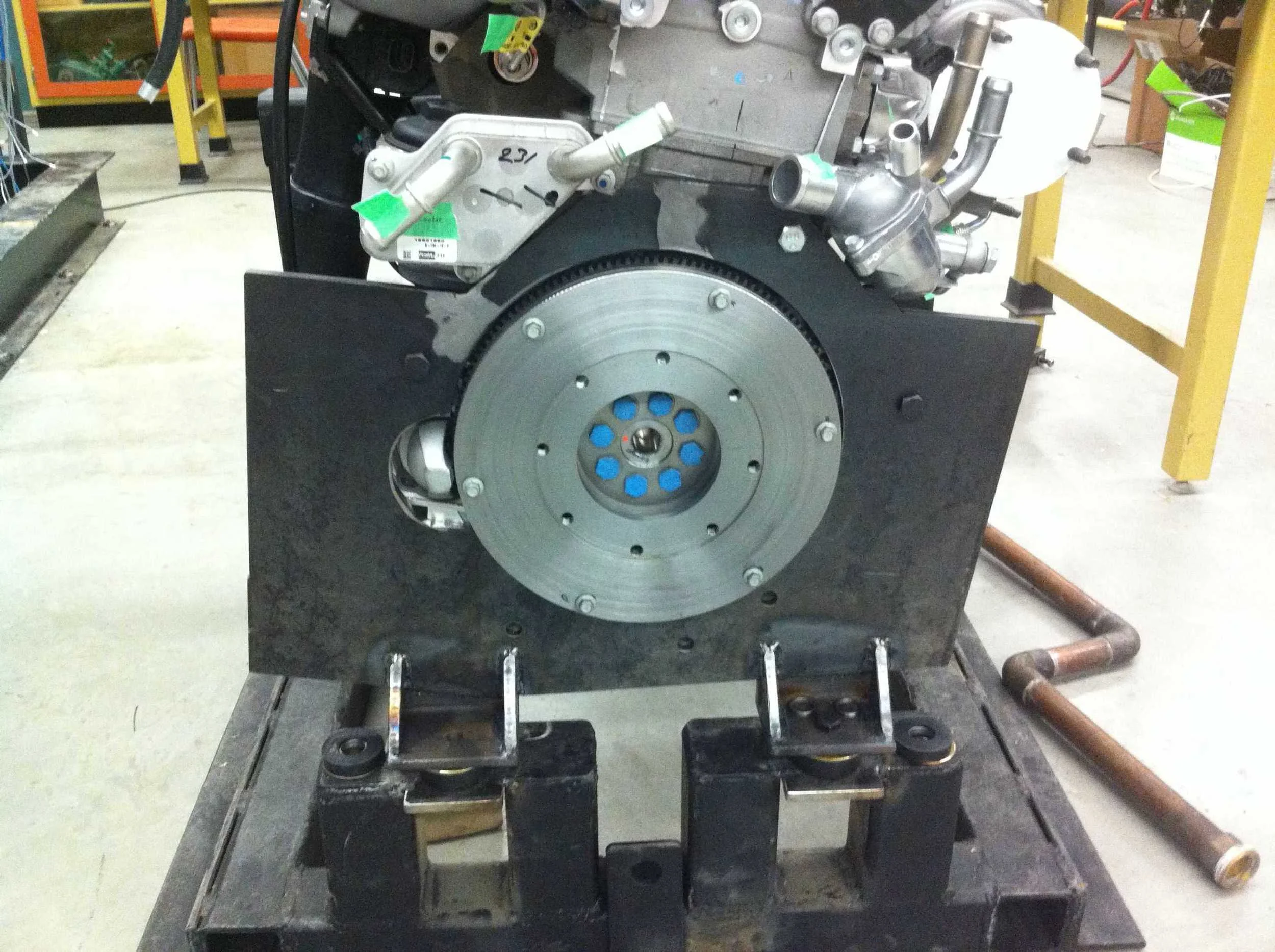

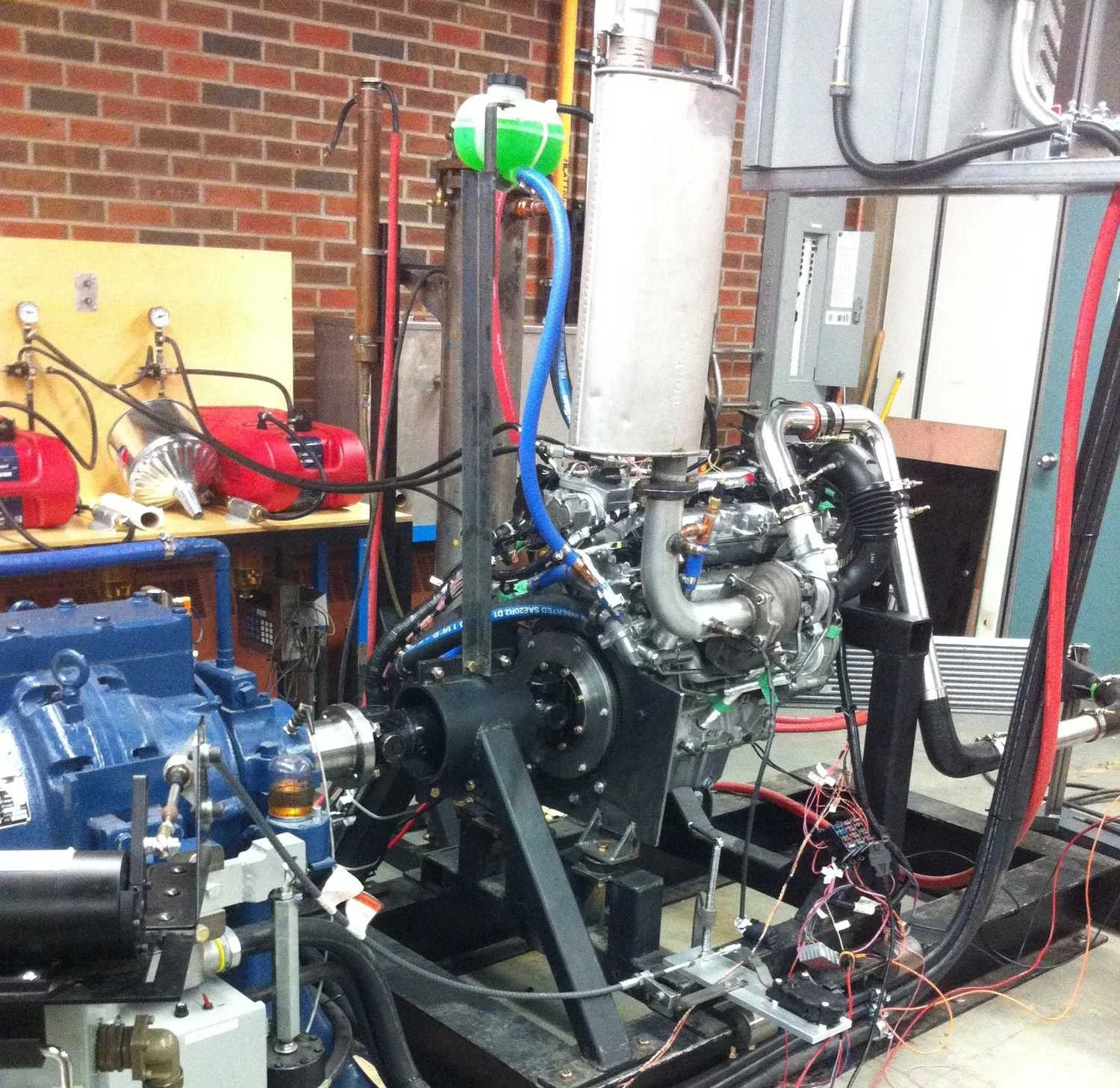

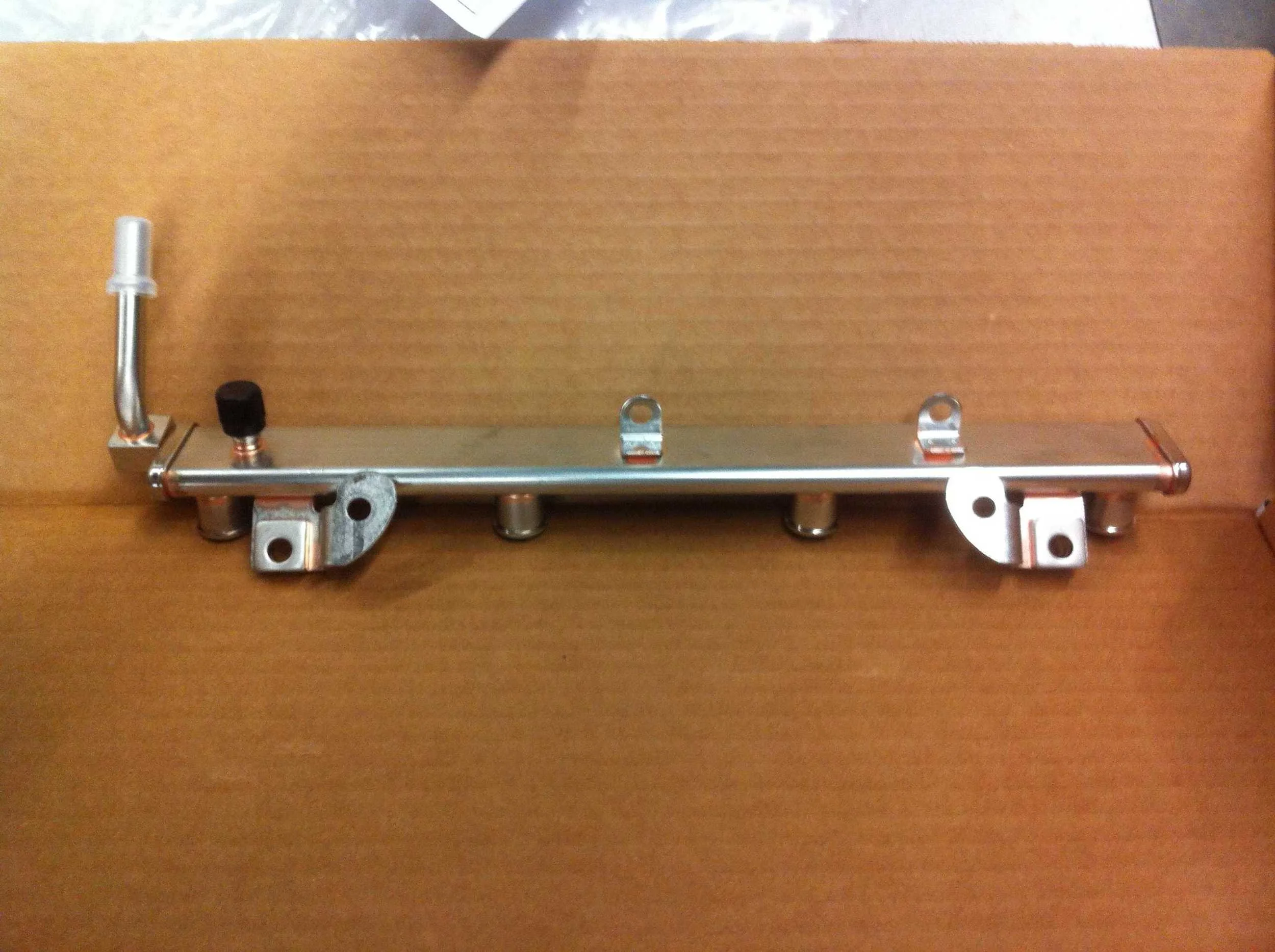

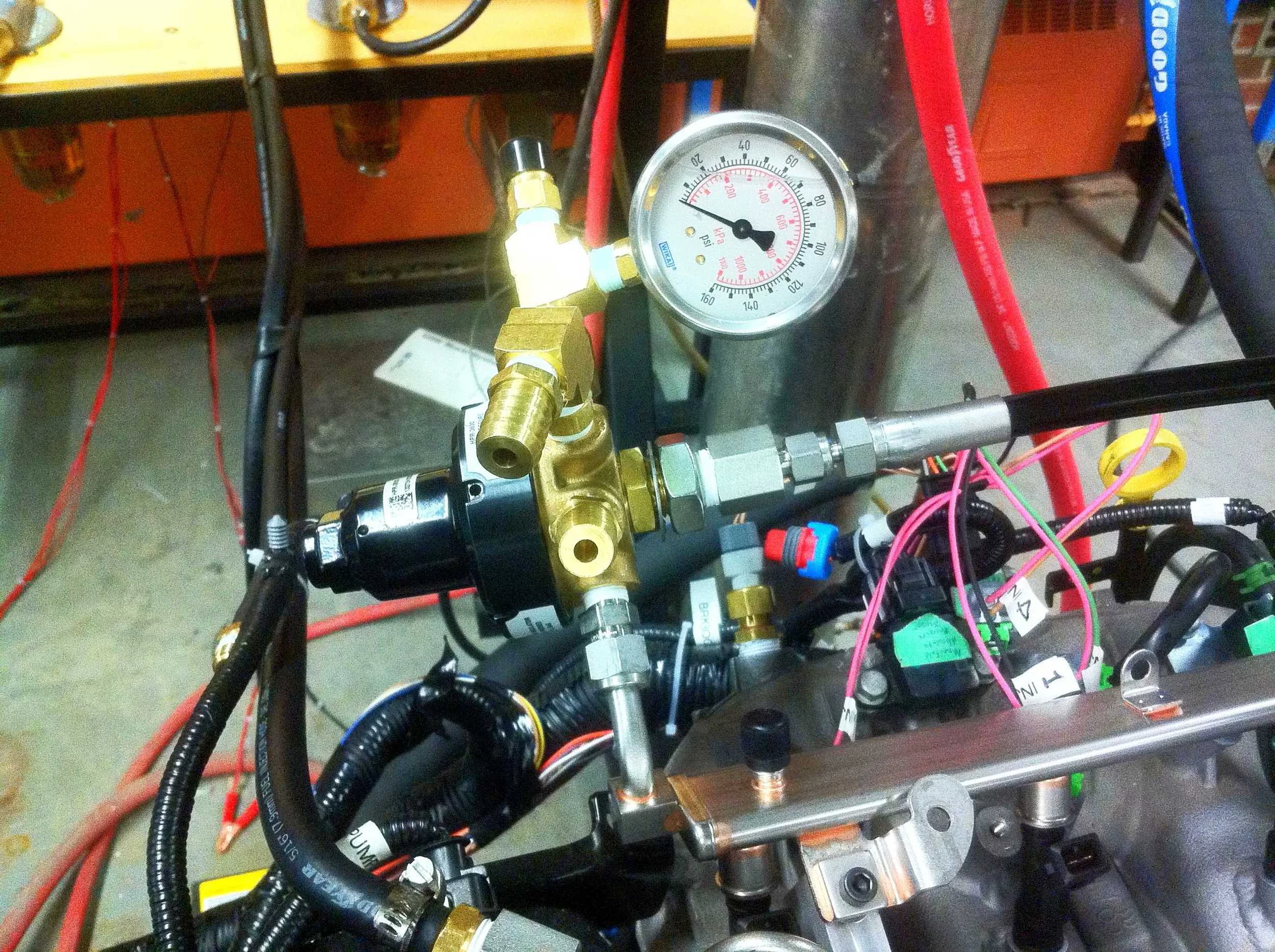

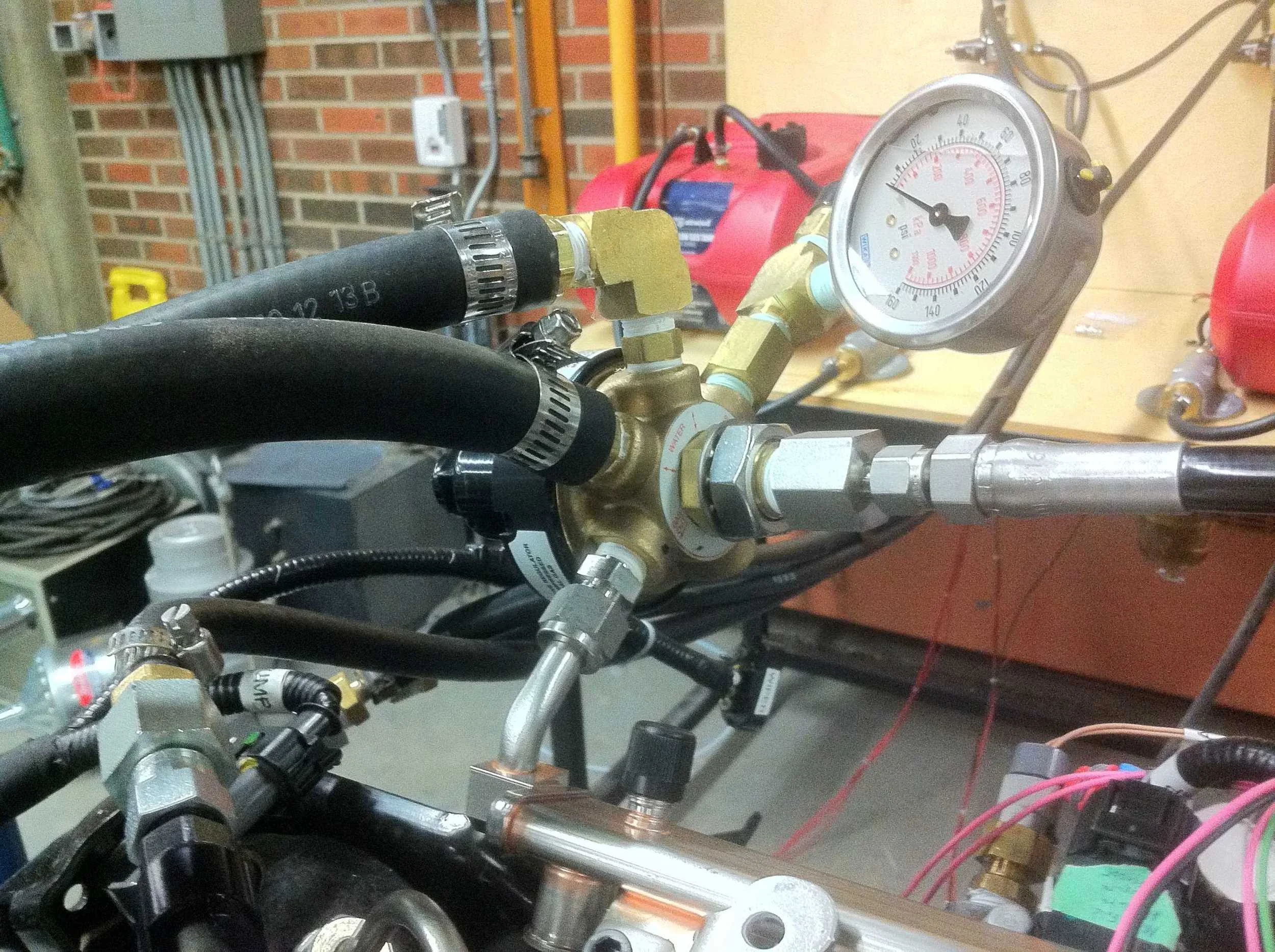

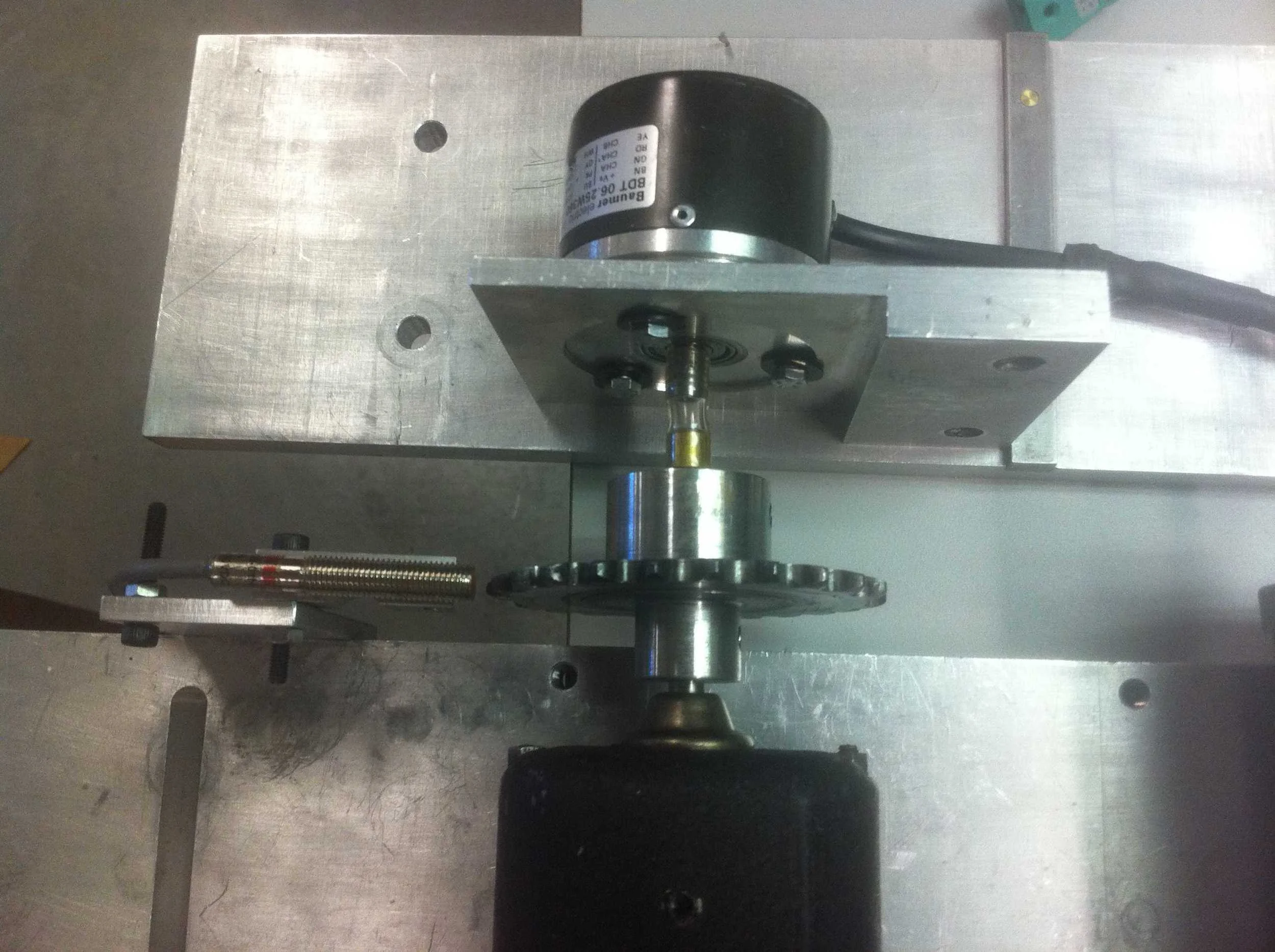

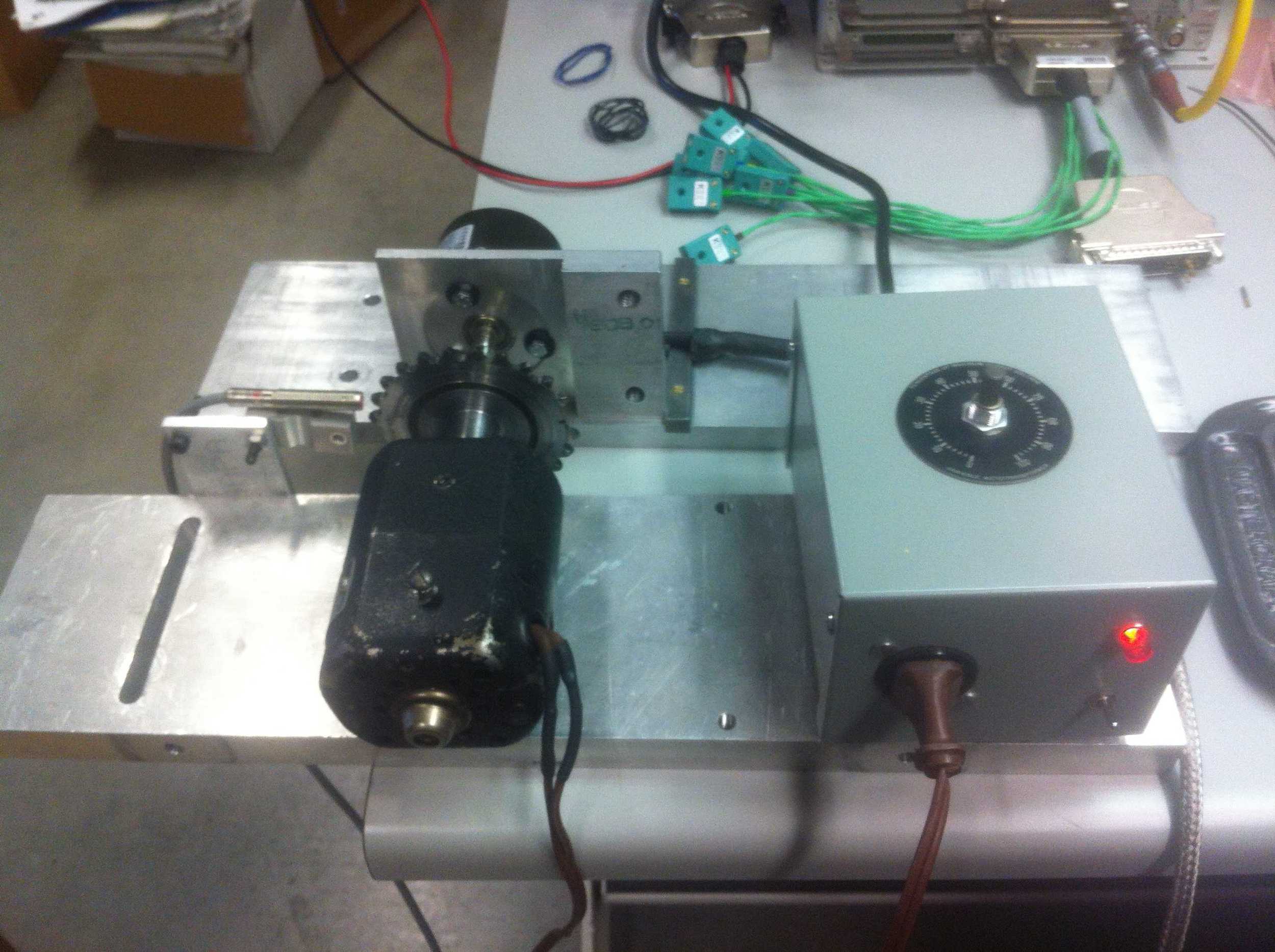

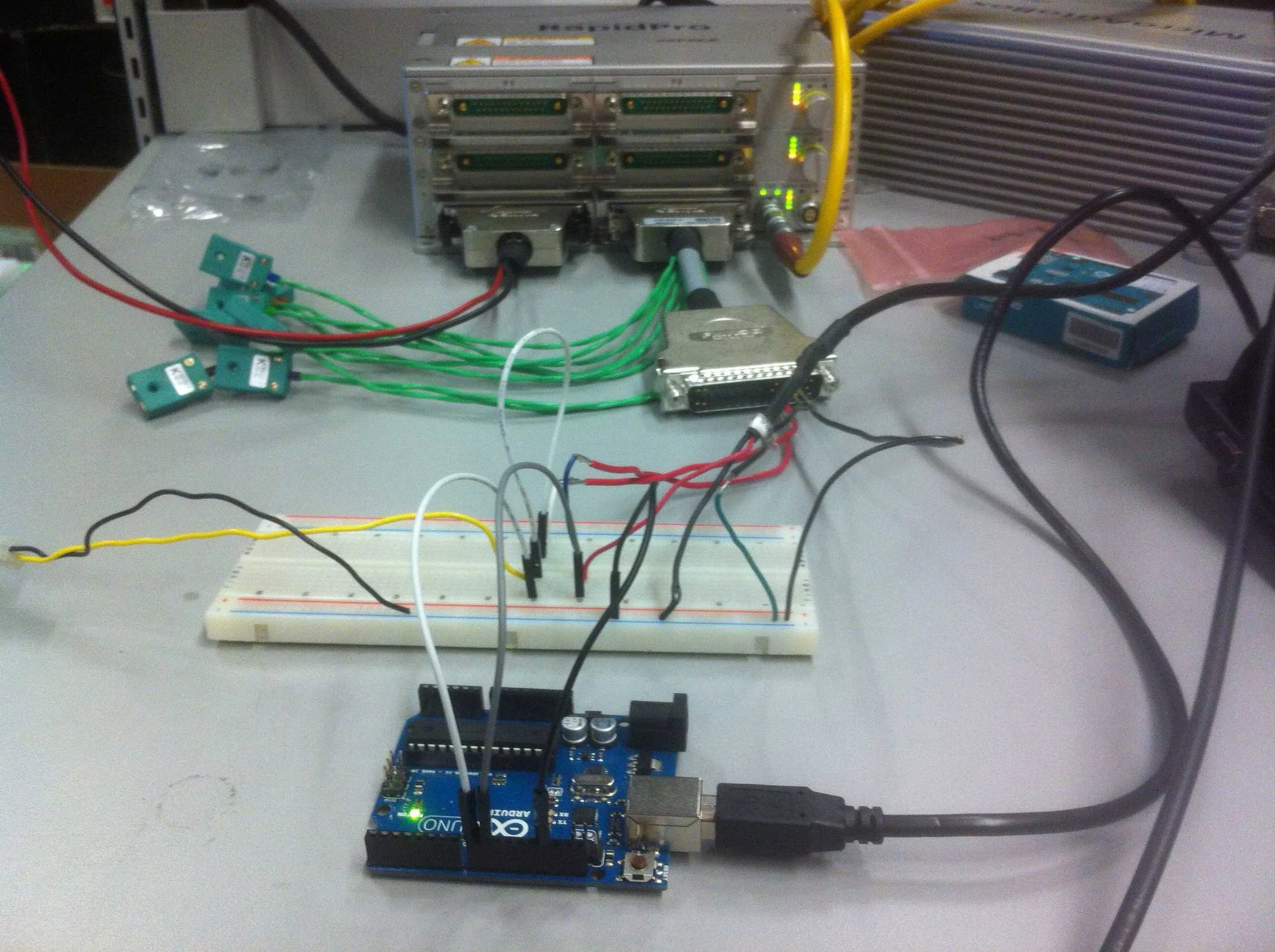

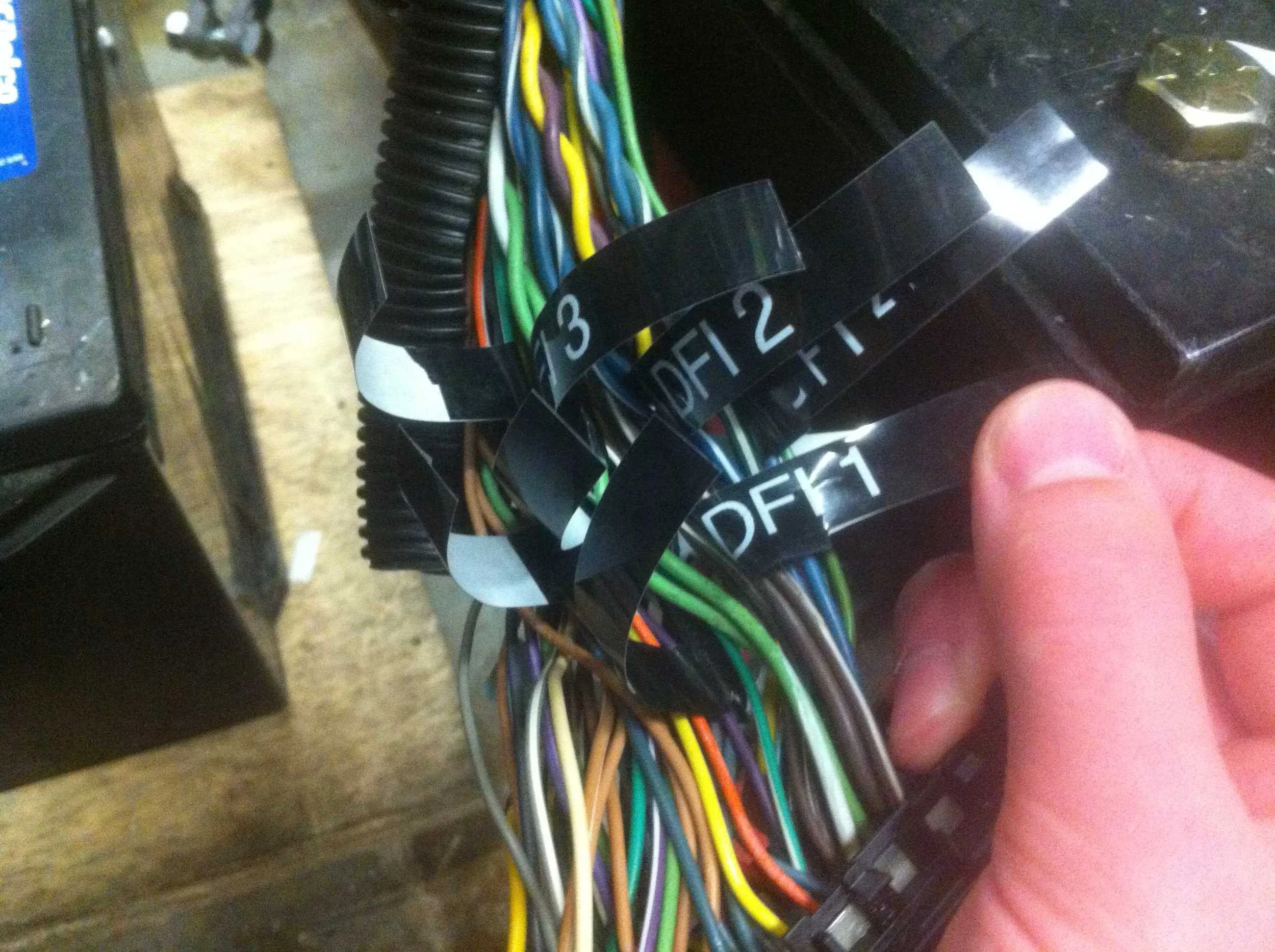

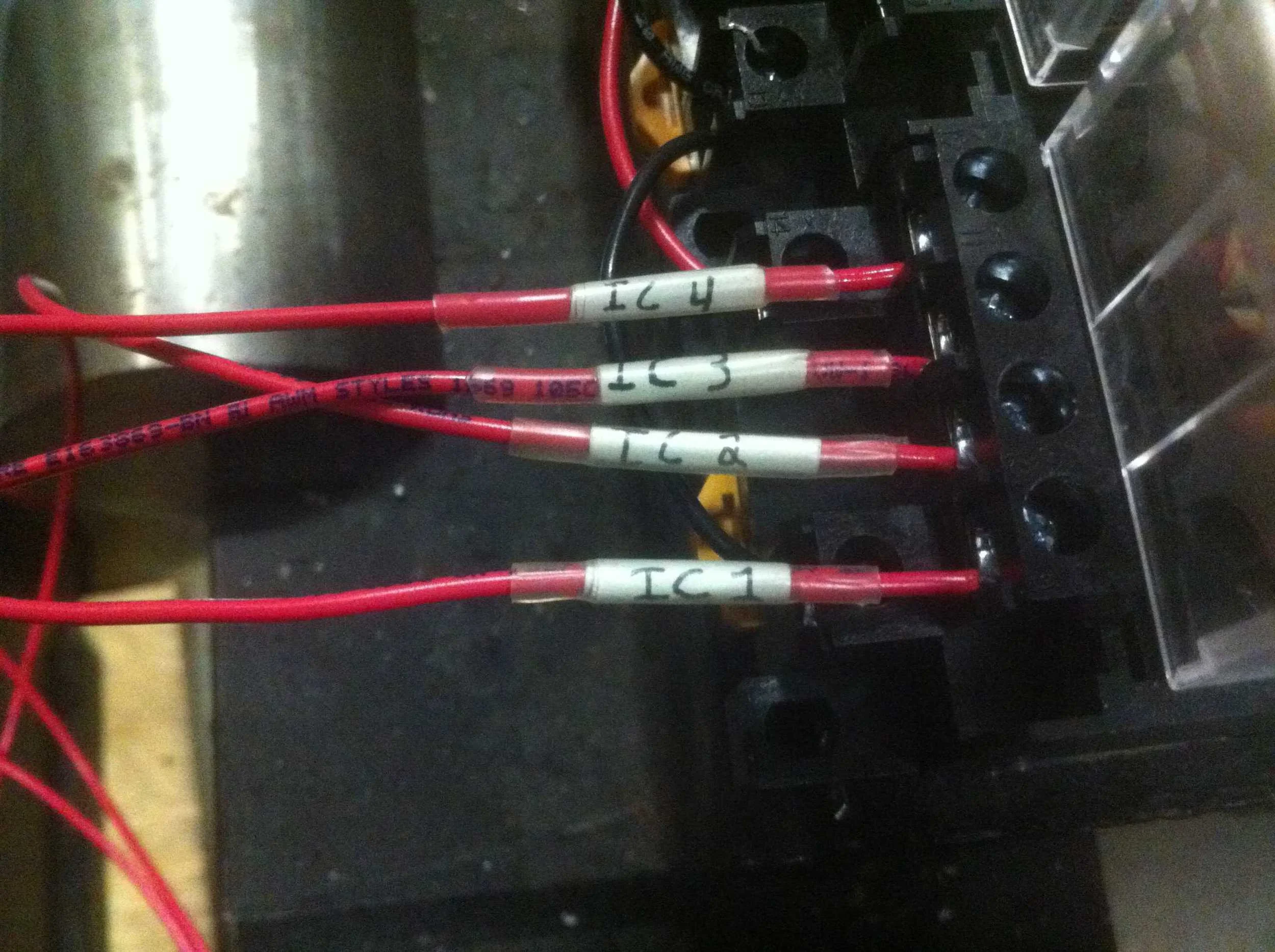

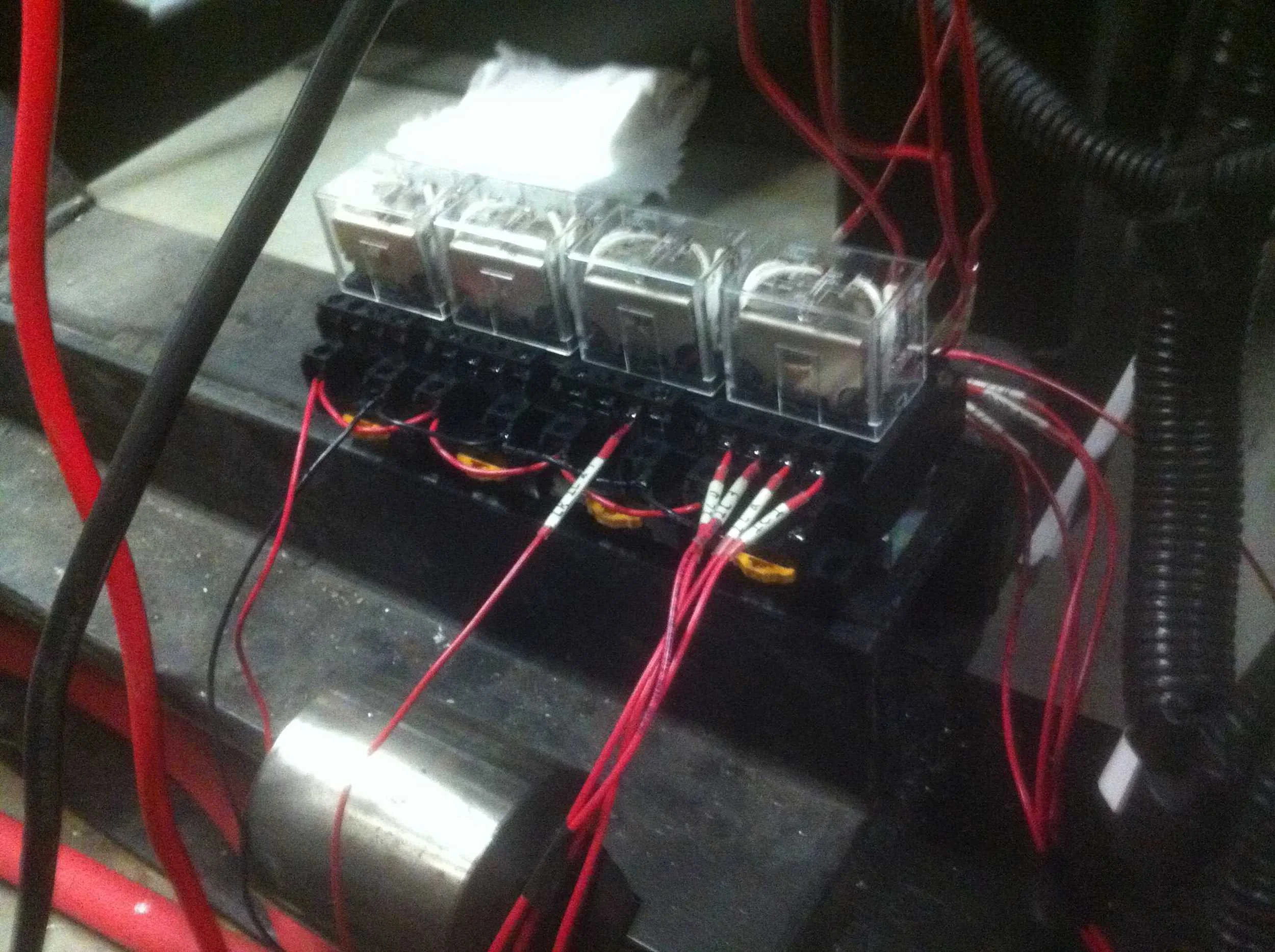

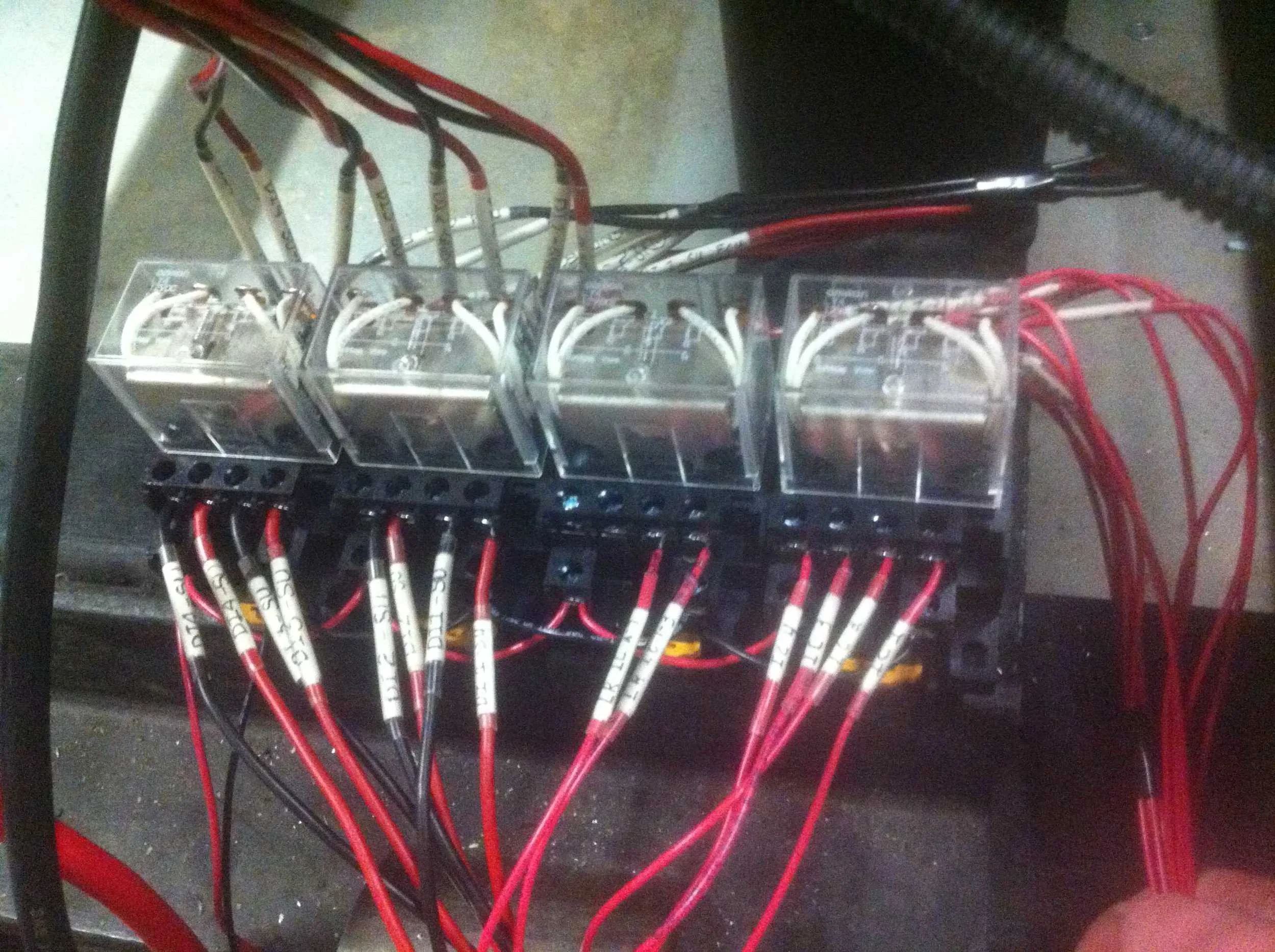

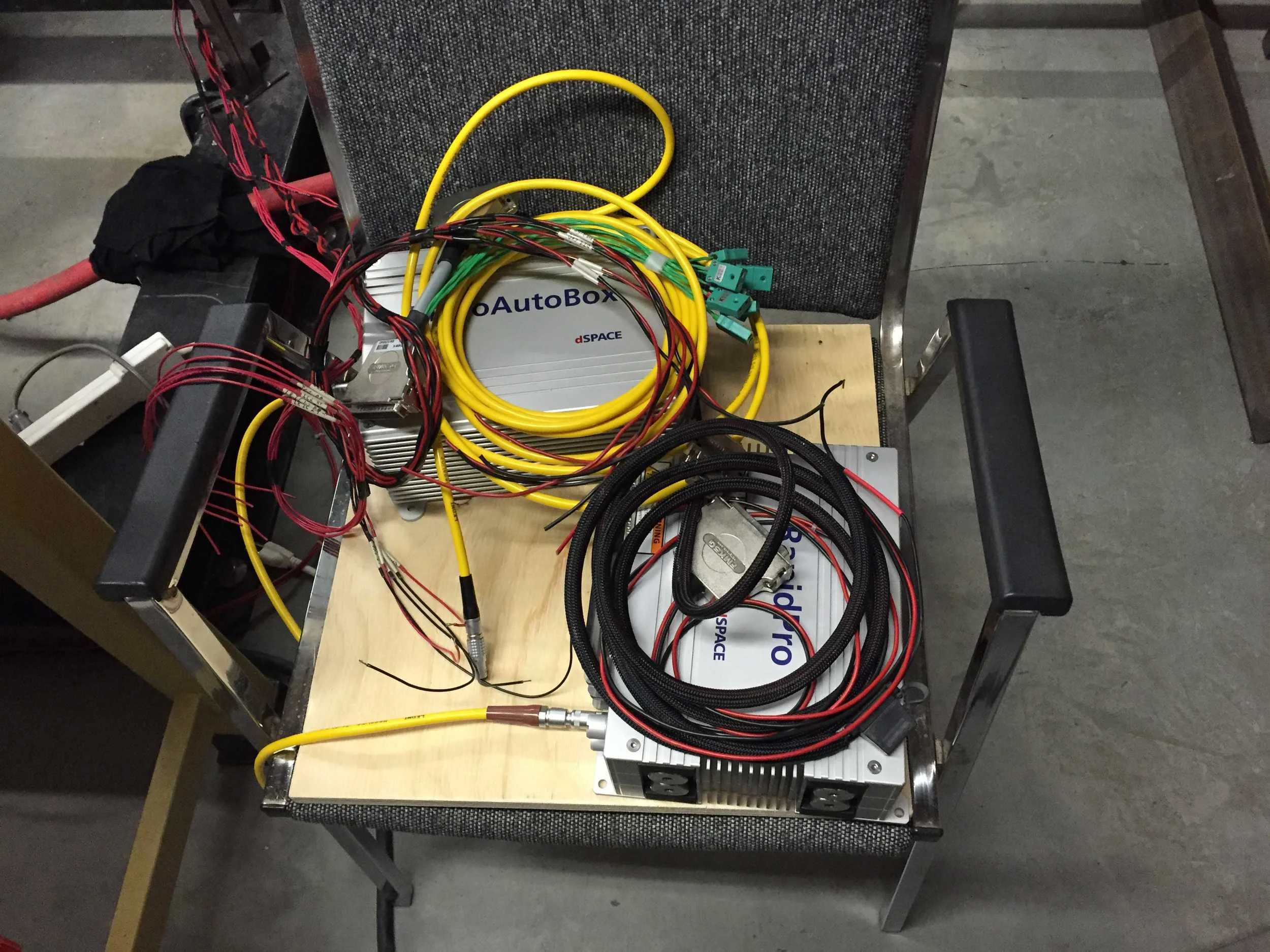

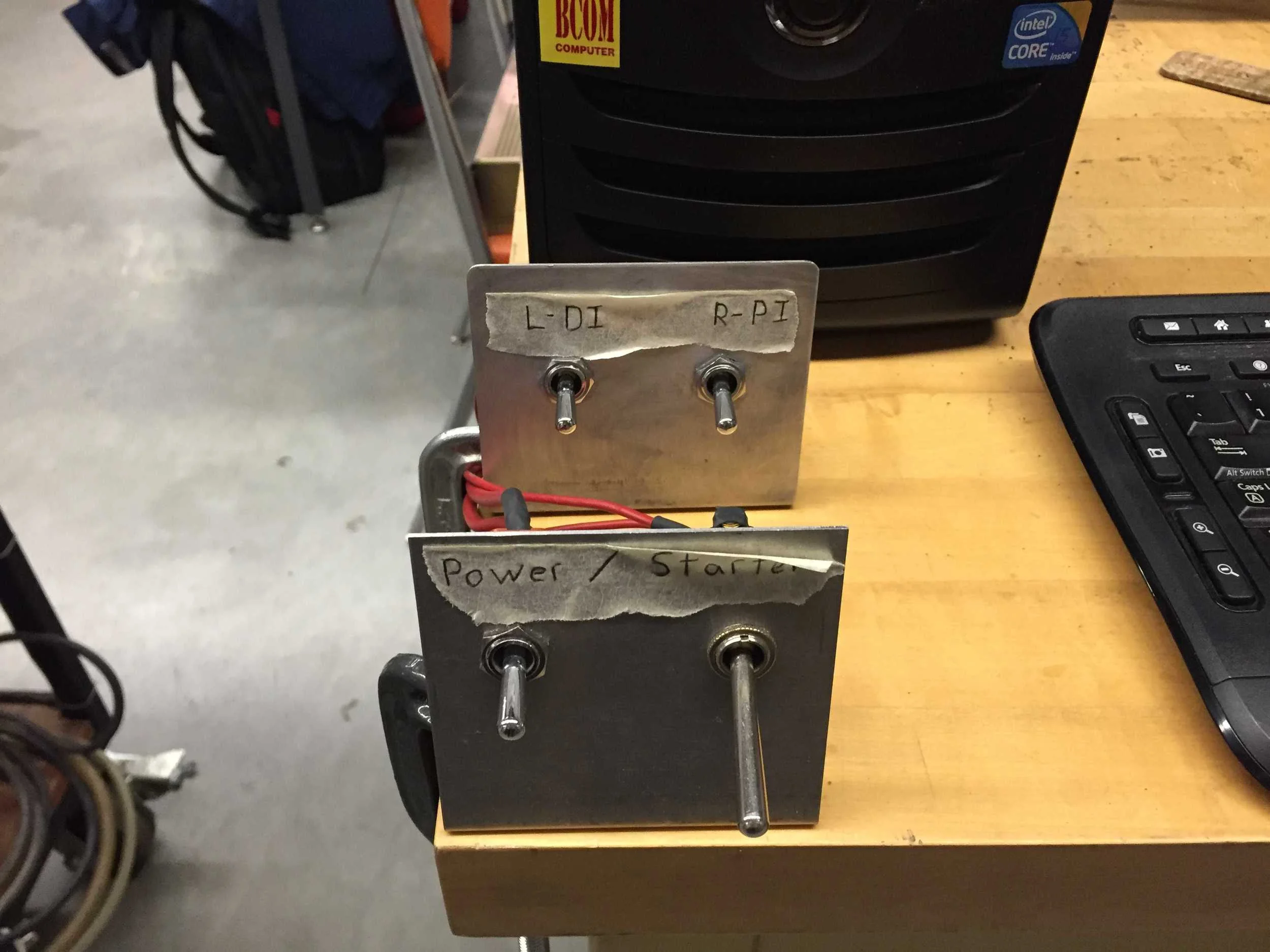

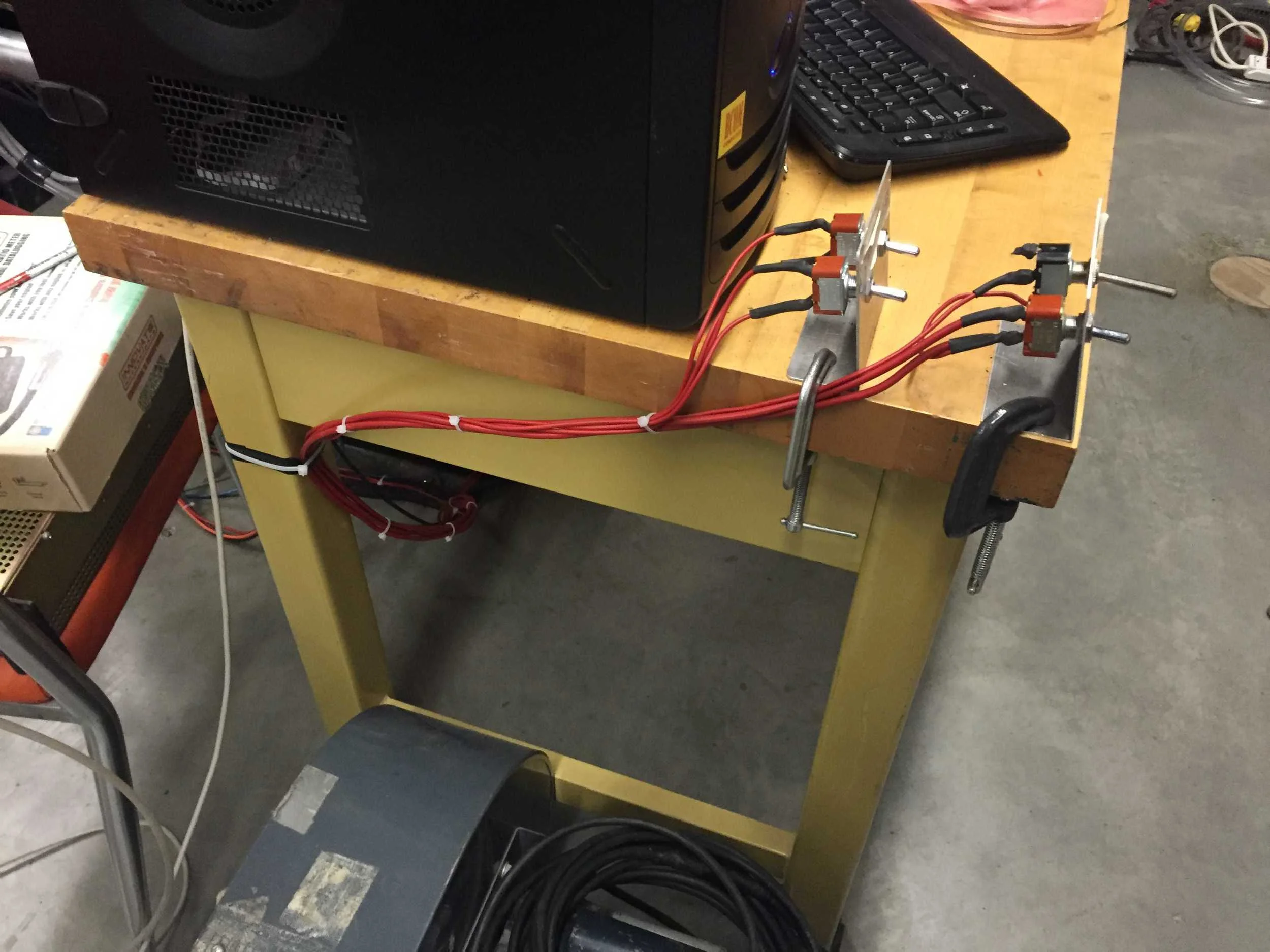

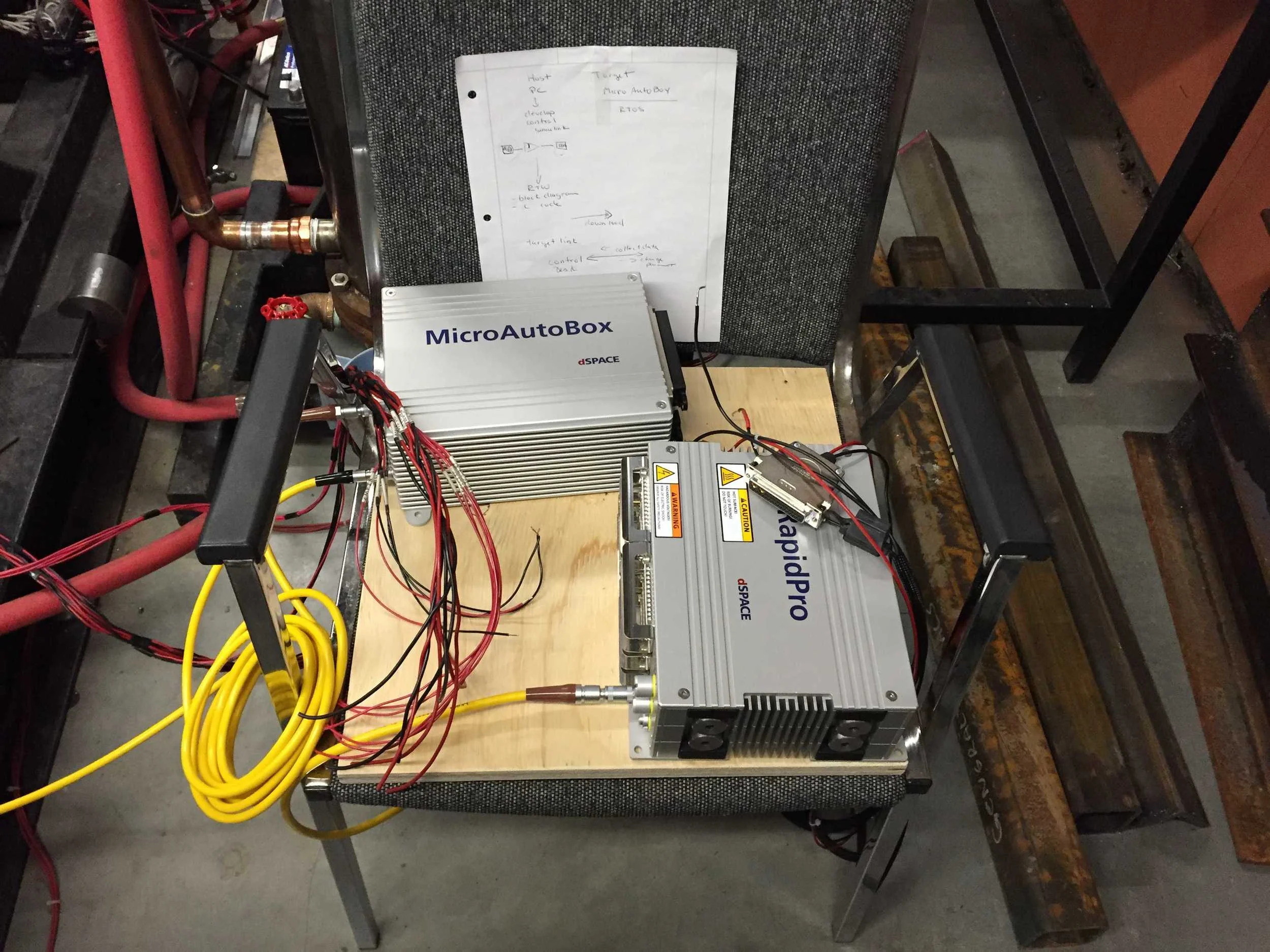

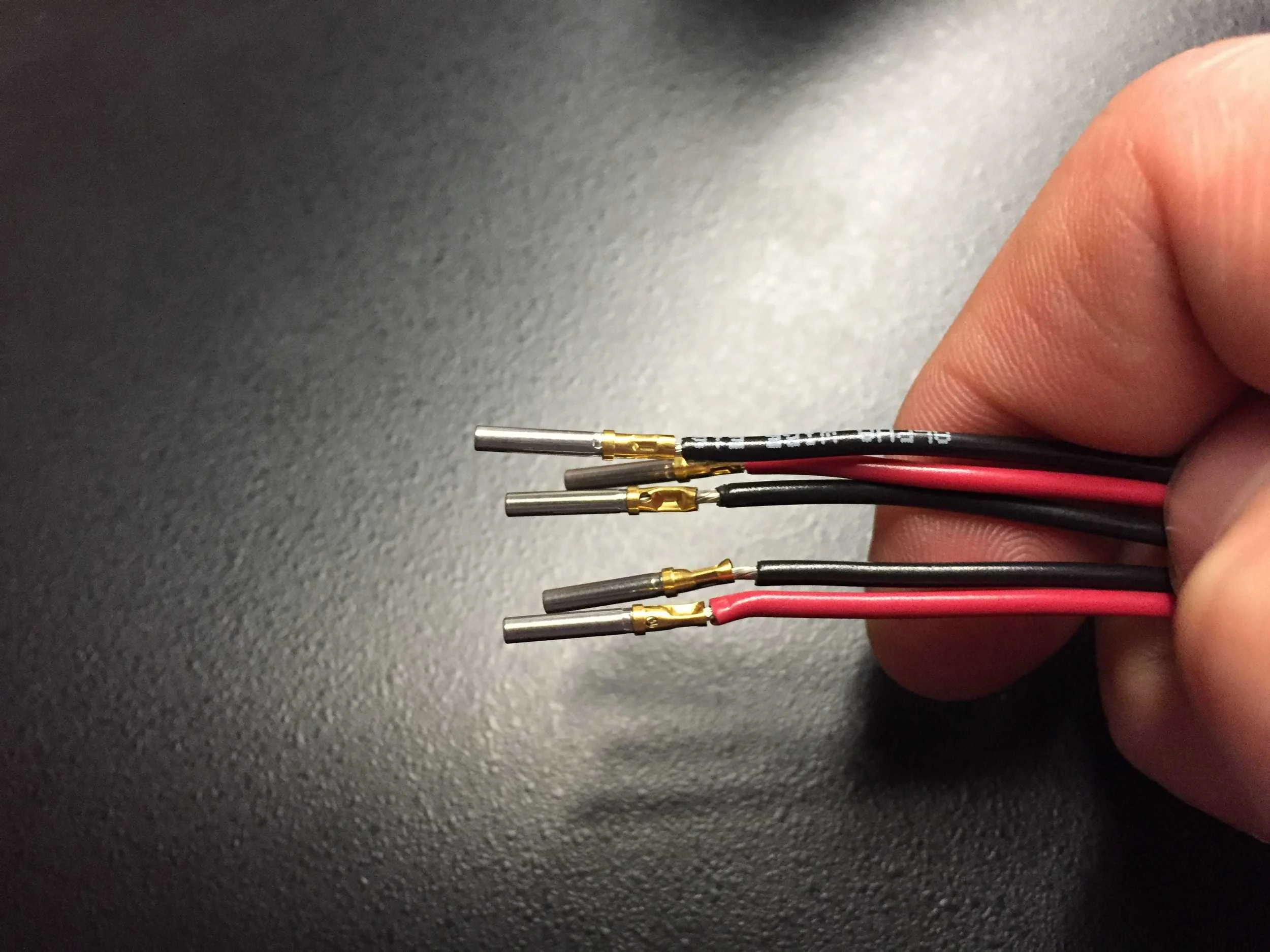

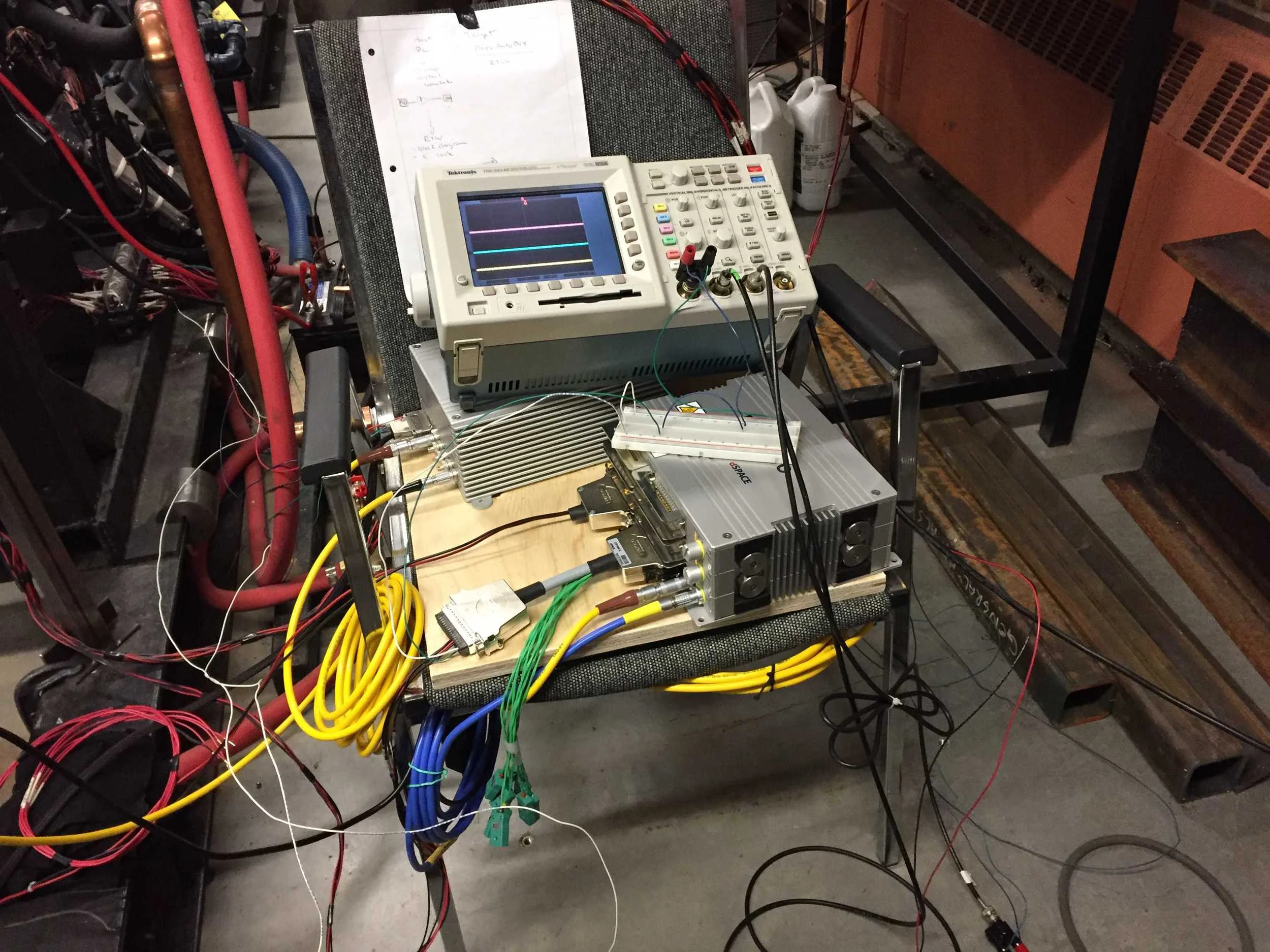

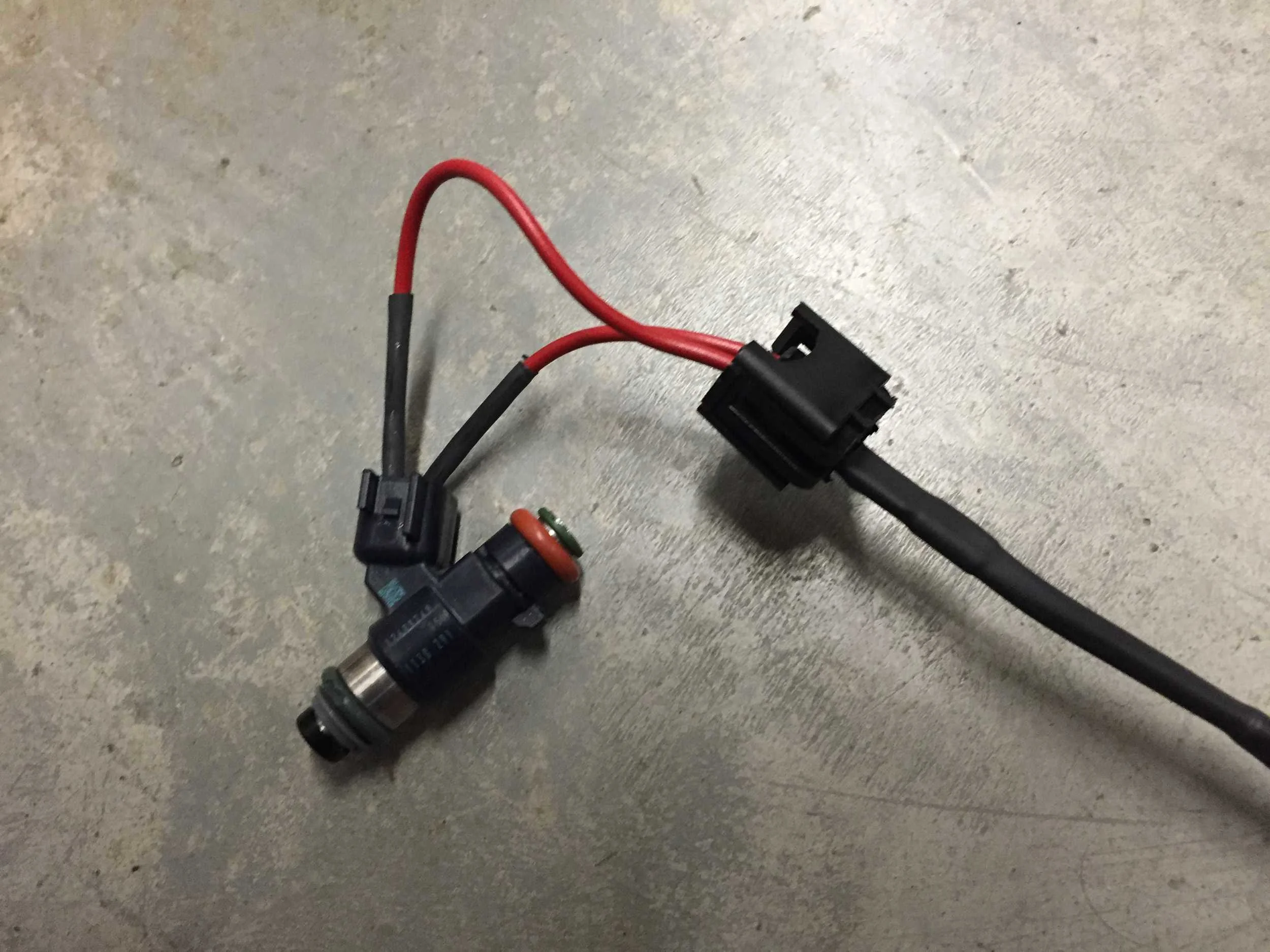

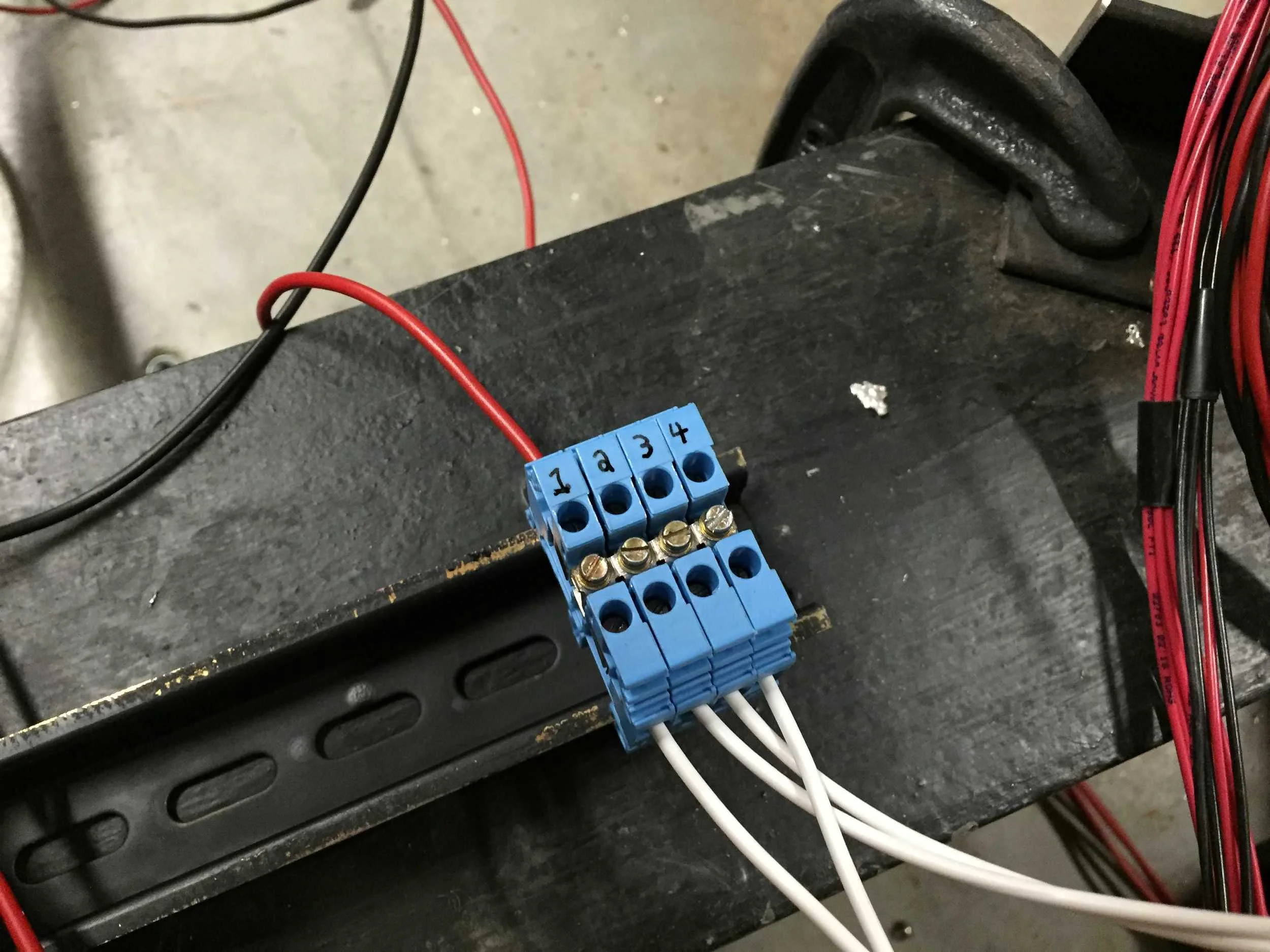

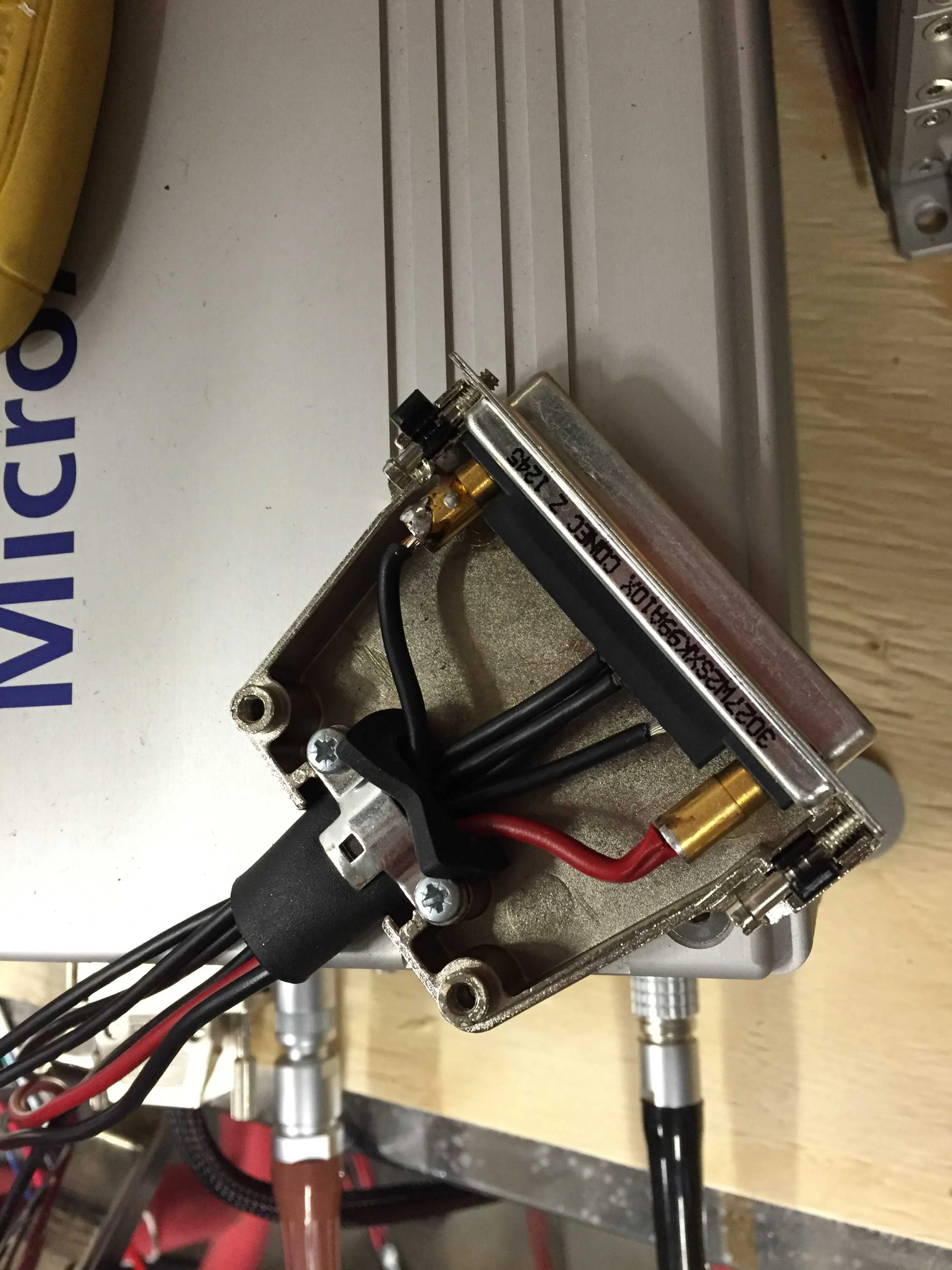

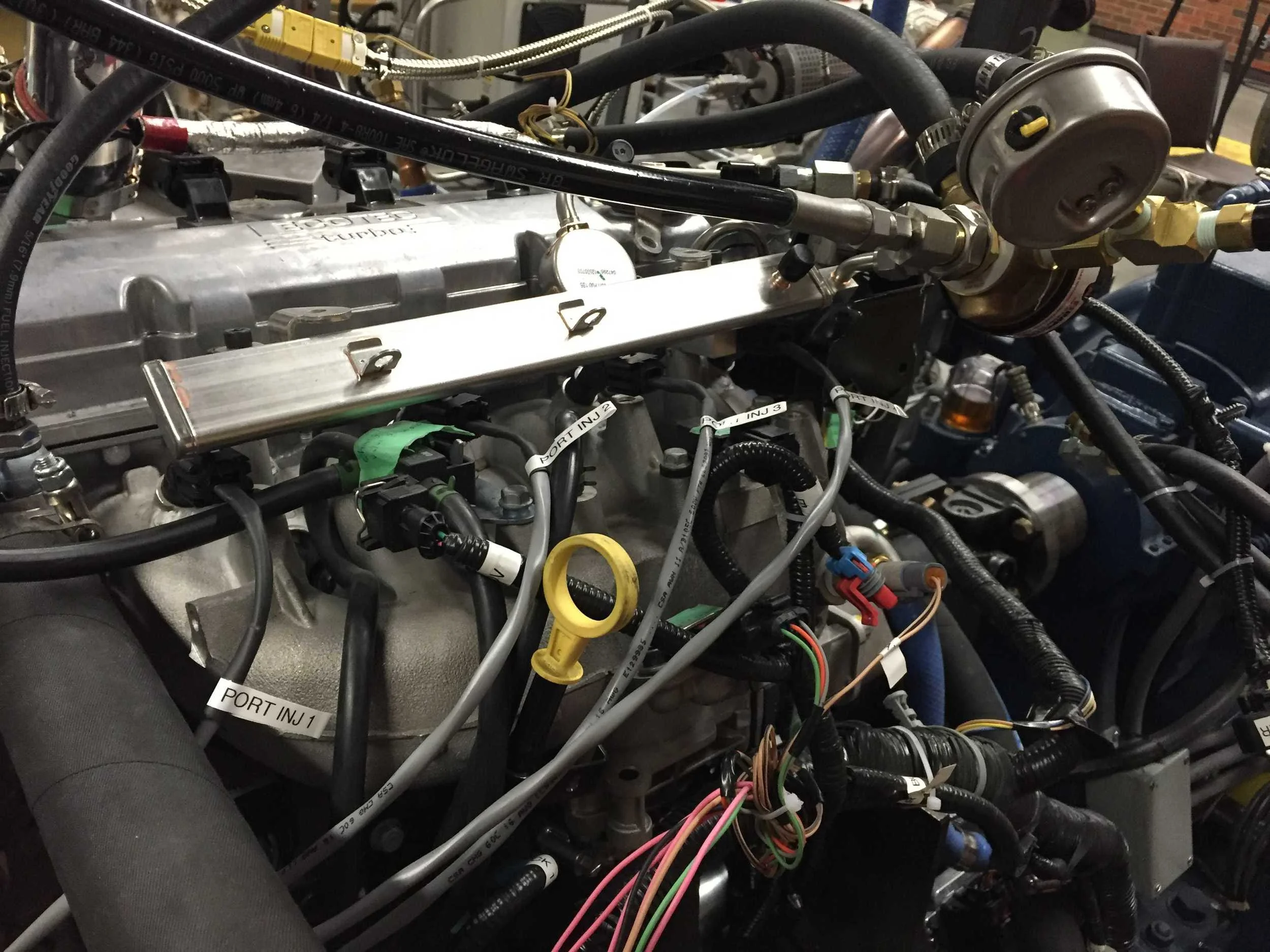

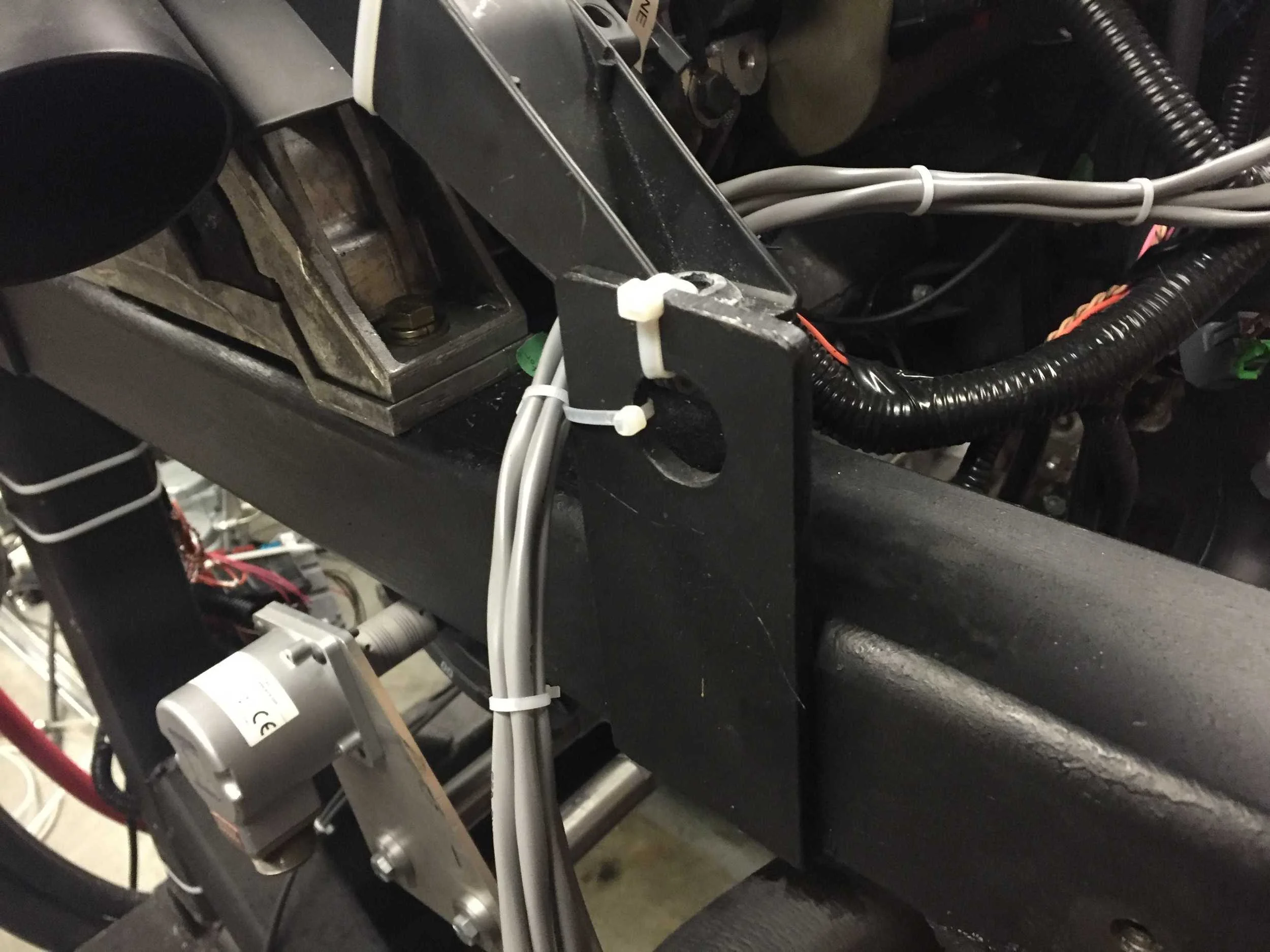

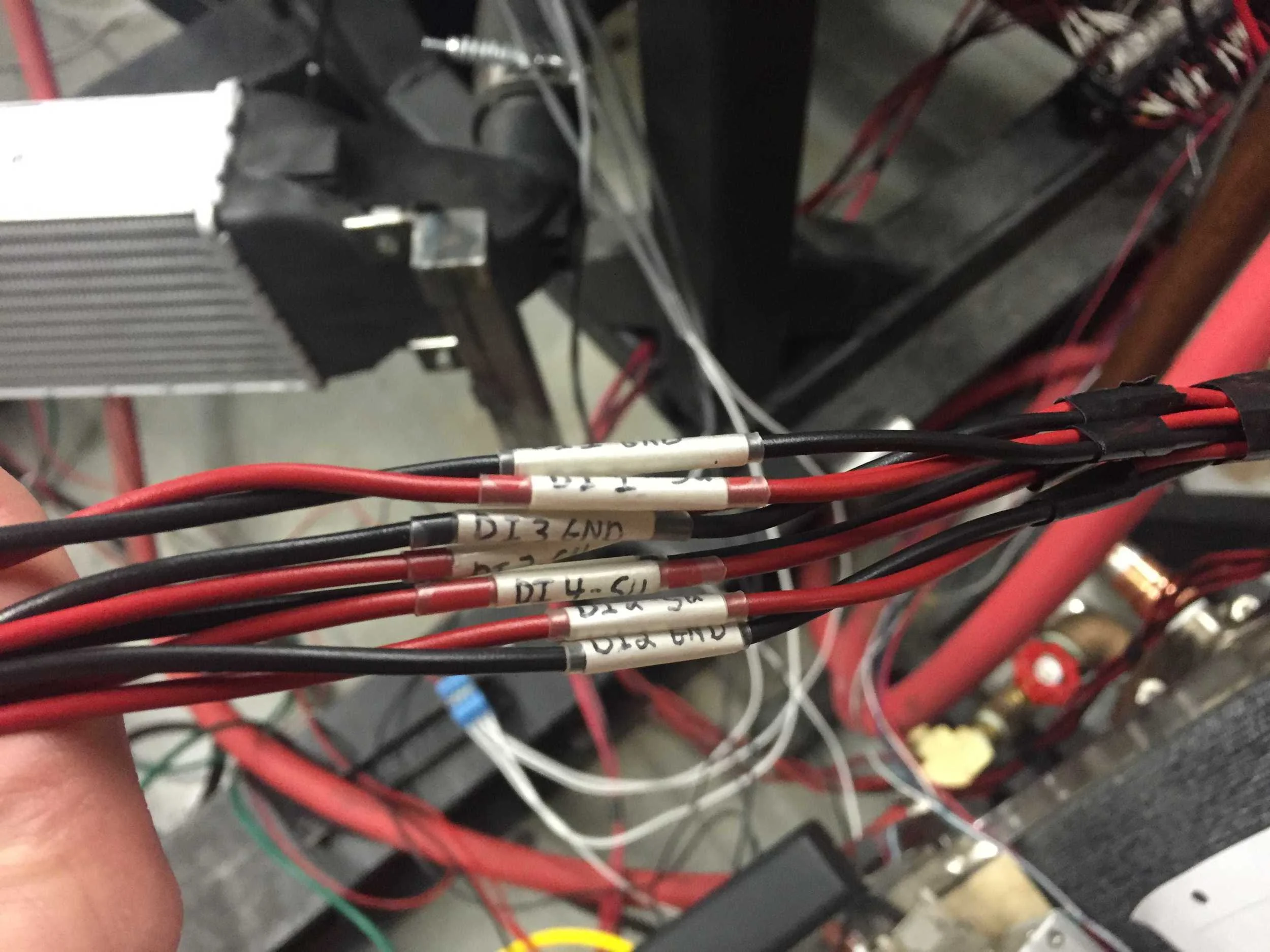

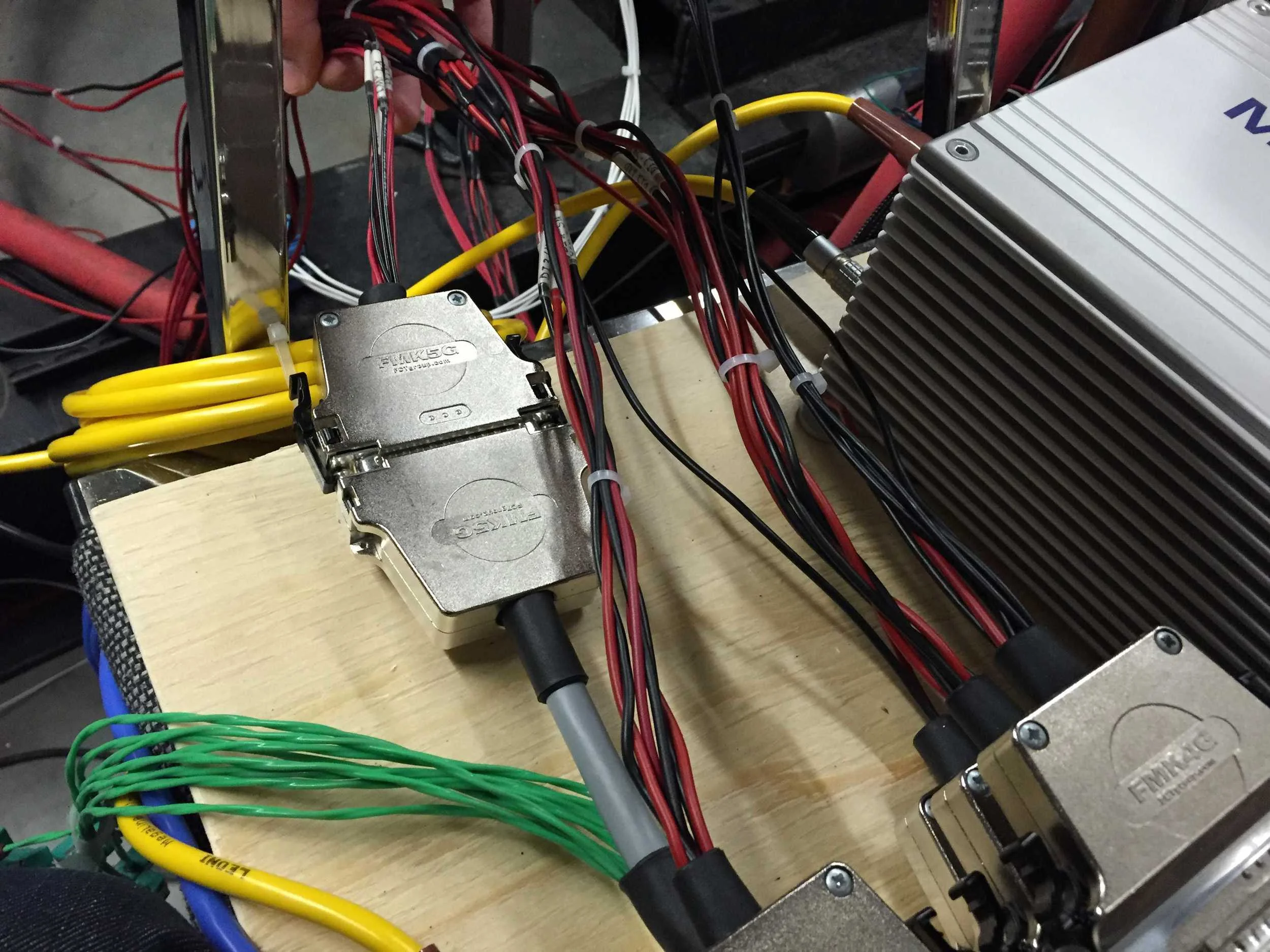

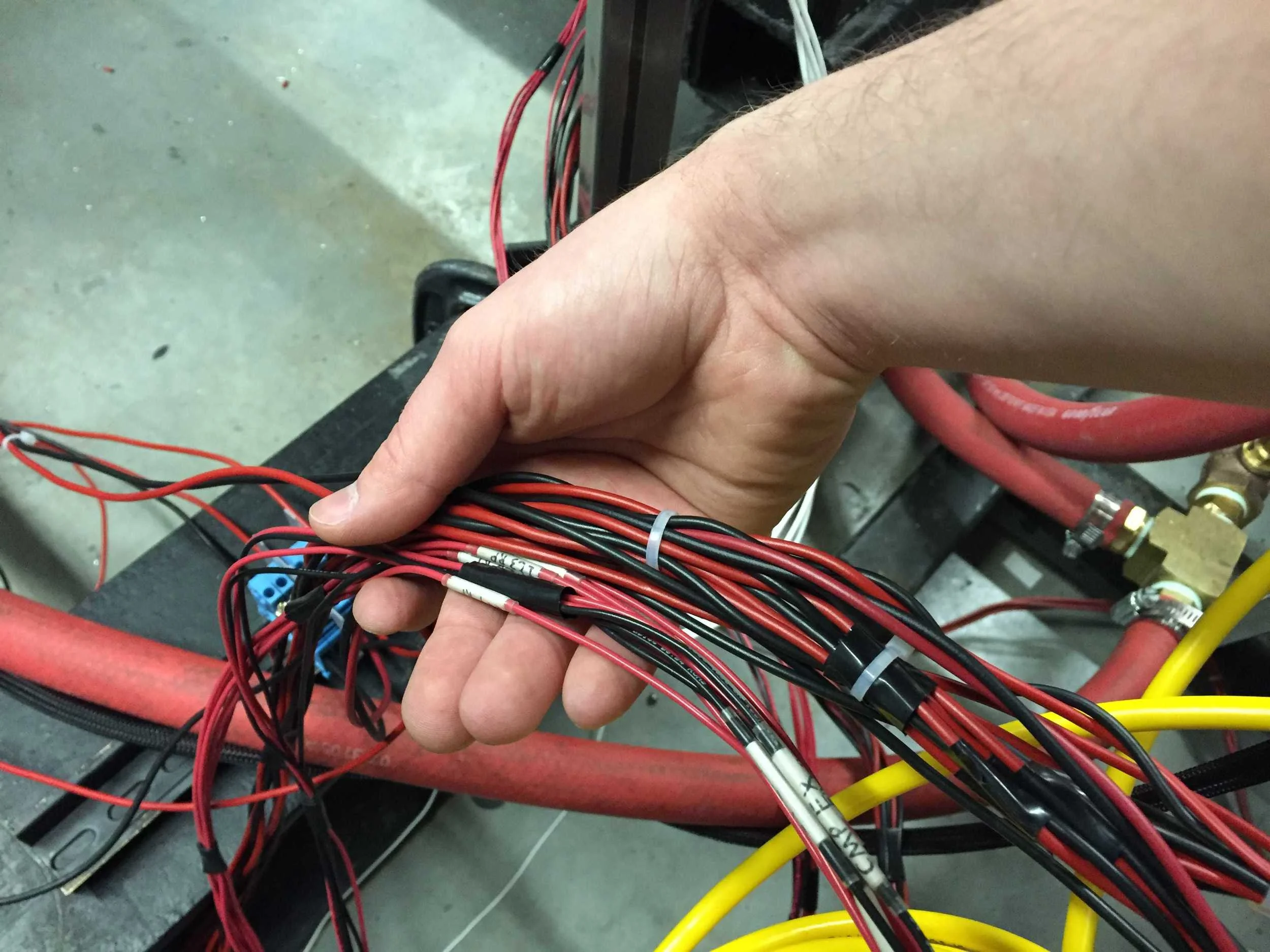

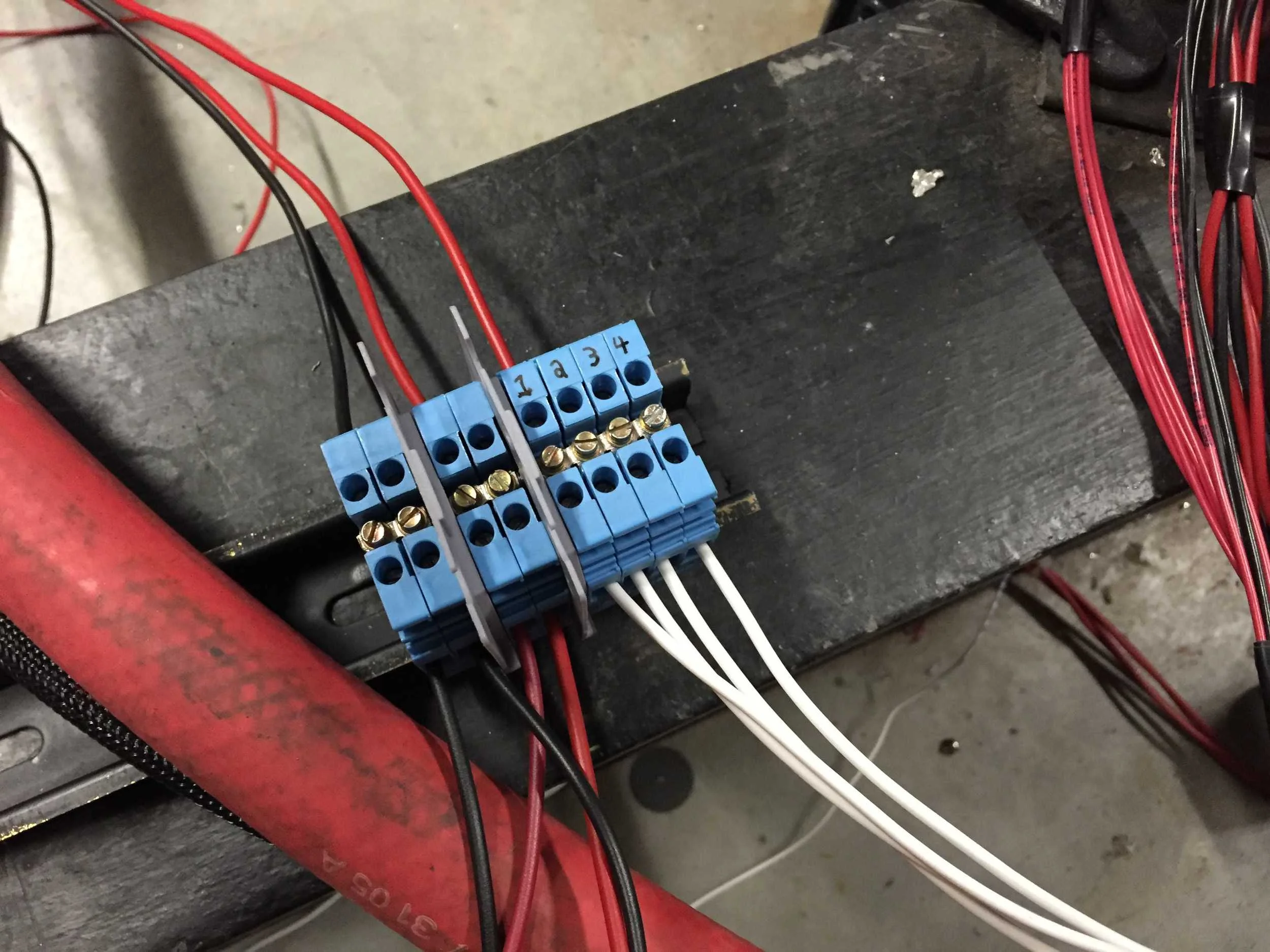

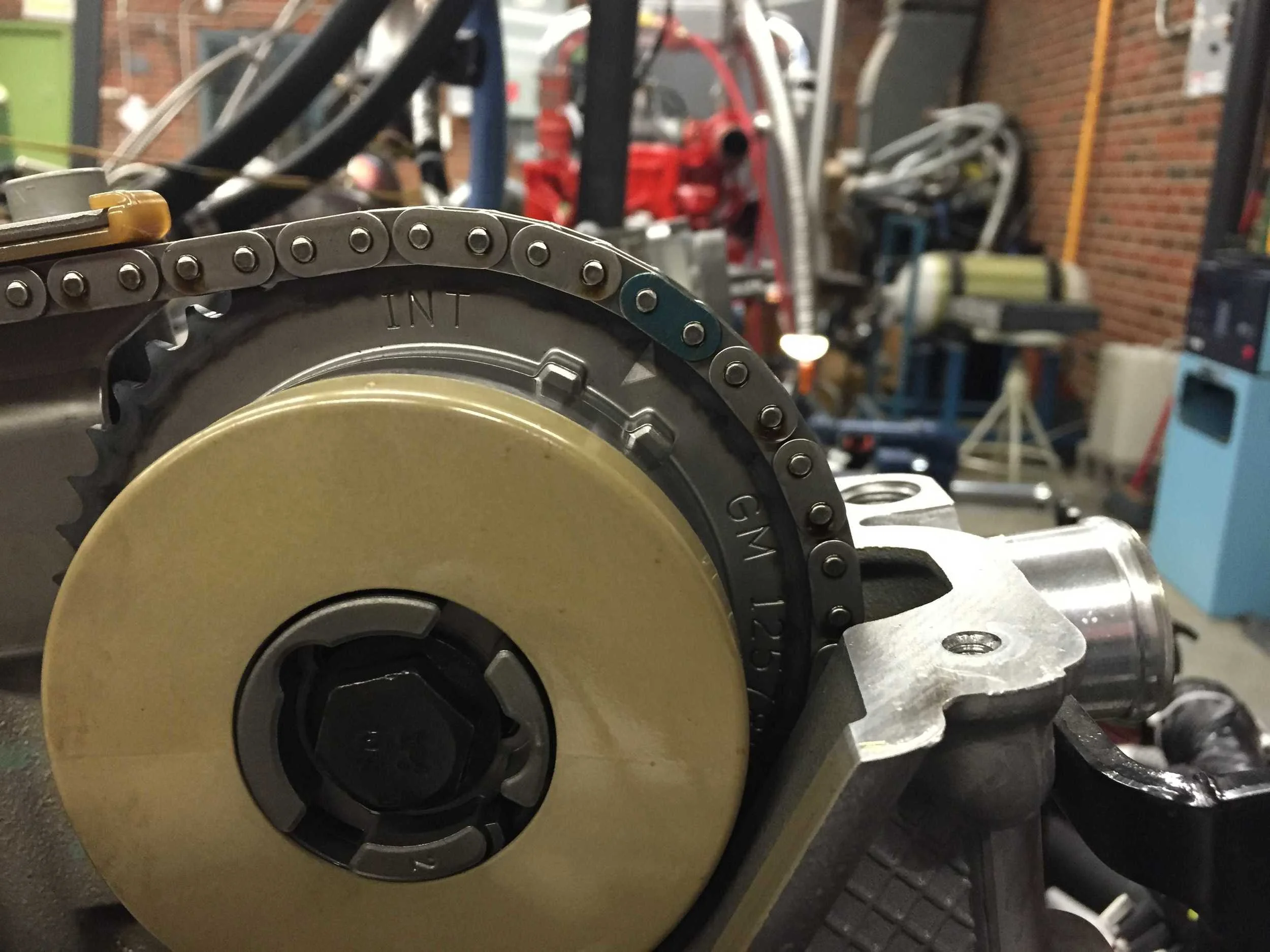

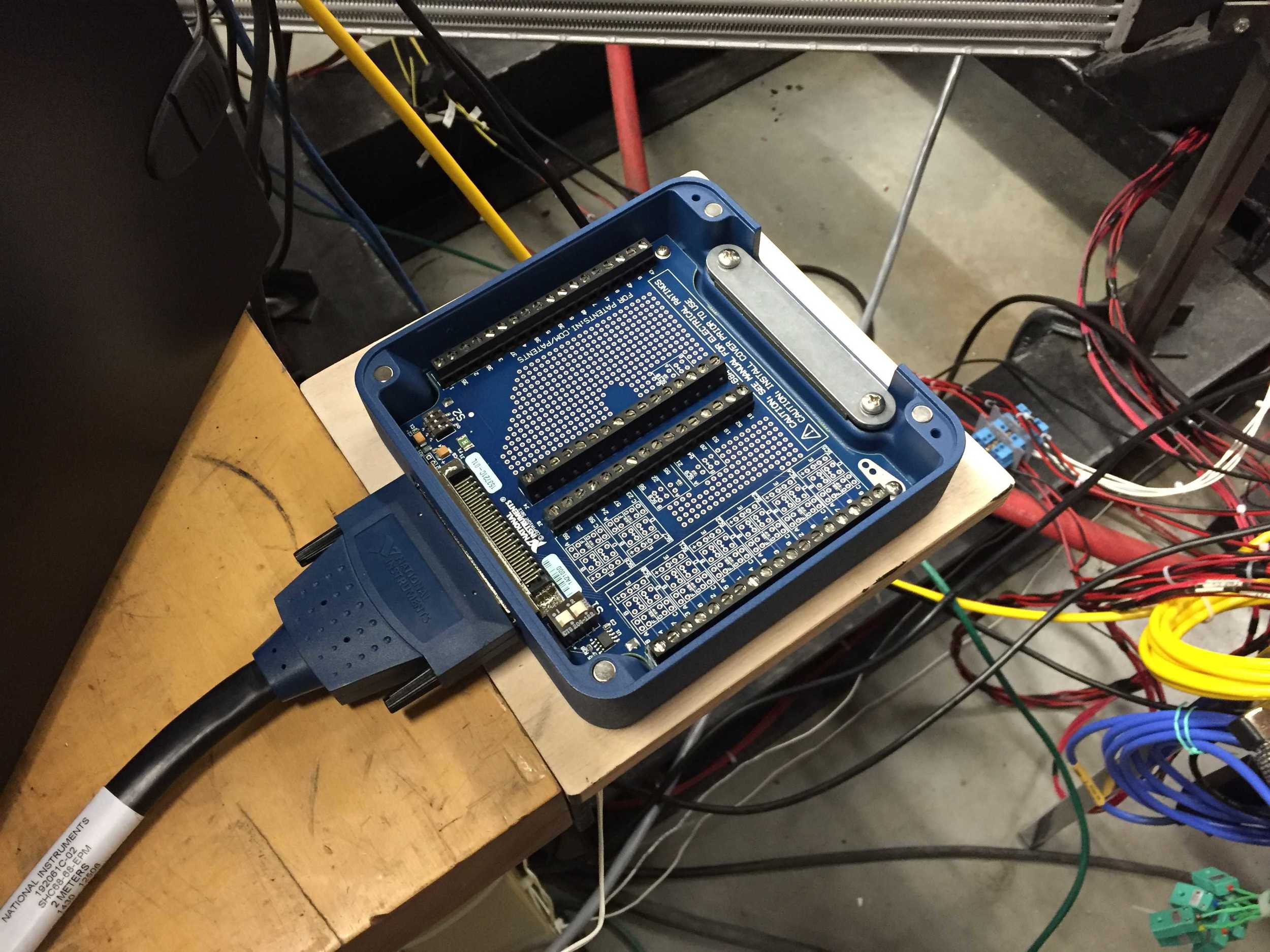

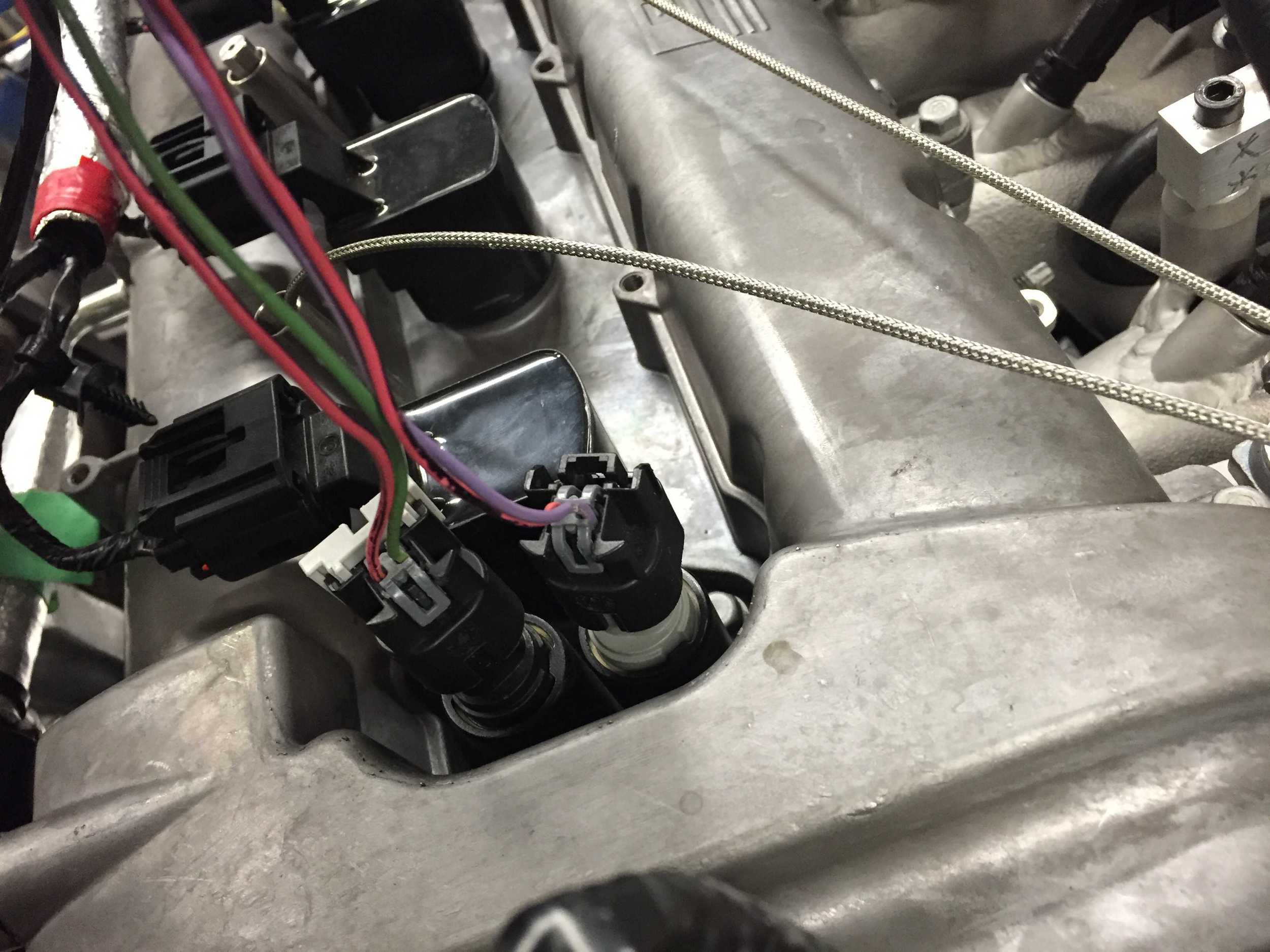

The gallery below documents my experimental setup for my master's thesis. While experimental setup is only a small section of your overall written thesis, it is very important for making your research unique and interesting. It is also a great learning experience not only in hands on elbow grease type work but also organization (keeping everything in order), documentation (the next student who uses it has to know how everything works), and communication (working with vendors, machinists, welders).

Click on the pictures to see a brief description of each.